Most people would hear the term tool making and assume it is about making hammers, screwdrivers and spanners. In actual fact a toolmaker is a trade professional who builds Moulds, Dies and jigs. They are an essential part of product development and the manufacturing of plastic products.

If you’re looking to get your product developed, then you need to consider exactly how it’s going to be manufactured.

We know that the manufacturing process can be complex. That’s why we’ve put together this behind the scenes guide to tool making to make your decisions easier.

What is tool making?

Tool making is the process of creating steel moulds that are used to produce plastic products.

A toolmaker is responsible for making precision tools (such as jigs, moulds and dies). But the toolmaker’s job doesn’t stop once they’ve produced the tools. They will then monitor these tools to identify and implement any necessary modification or repairs.

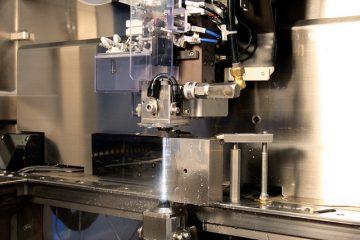

Tool making requires high precision, so that parts can be made accurately again and again. A toolmaker makes plastic injection moulds, blow moulds, press tooling and jigs & fixtures.

What does a toolmaker do?

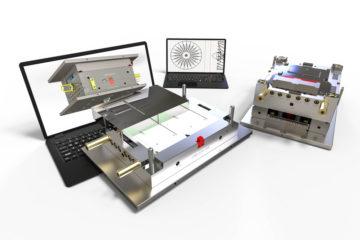

Toolmakers understand the product’s design and create the moulds needed to manufacture plastic products. Toolmakers often work in specialist machinist shops. They use equipment such as CNC machining centres, wire cutters, EDM, lathes, milling machines, and grinding machines.

Toolmakers need to have a mix of both technical and digital skills with the ability to think or see in mirror reverse. They often work with computer-aided design (CAD), and computer-aided manufacturing and machining tools such as a CNC machine to complete their tasks.

Tool making is an incredibly precise trade. With parts flashing at just 0.03 of a millimetre, it is imperative that the toolmaker has built the mould to precise specification to ensure that the moulded parts are produced to the highest quality and repeatability.

Why is tool making important?

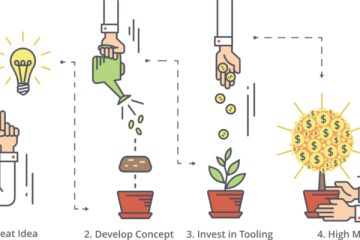

To create the best product, you need tools that are specifically designed and engineered for the job. If you are looking at mass producing your product, injection moulding is most likely the best method to use. In order to injection mould your product, you will need a toolmaker to build the mould for it.

Good tool making also influences how quickly and accurately a product can be produced. It is crucial for high-volume or mass-produced products because it makes the process easily repeatable.

An understanding of tool making is important when you are designing a product so you can ensure it is designed correctly and able to be manufactured to a high quality and efficiency. Here at Dienamics, our designers all have a good understanding of tool making and injection moulding, along with having access to a working tool shop with qualified toolmakers who assist and advise in the design process.

Now that you know a little about tool making and how it influences product design and manufacturing, you should have some understanding on how important the tool making stage is to product development.

Looking for tool making in Brisbane?

At Dienamics, we have over 30 years of experience in industrial design, tool making and manufacturing in Brisbane. We offer specialised tool making services to help you take your concept from an idea to a reality.

If you think tool making might be a manufacturing option for your product, give us a call and talk to our expert team today.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox