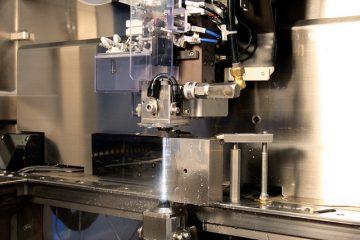

What is Machining and Milling? Machining is an umbrella term for a range of process which generally use cutting blades to cut away material from a workpiece. These can by computer-controlled machines (called CNC) or operator controlled machines (called conventional).

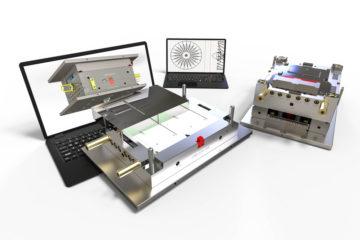

The common element of both CNC and conventional mills is that they have a cutter attached to a spindle and they cut along three or more axes in space. They also have a work bed, which locates your workpiece and ensures that it doesn’t move. In conventional mills, it’s usually the work ben the moves around the cutter or endmill, but in Most CNC mills, the work bed is stationery, and the cutter moves around the workpiece.

Machining is one of the simplest and most straight forward was to make something. First you get a block of material, and this can be just about any material. You clamp it to the work bed and machine away the material until it you are left with the desired result. Obviously, there are some limitations to this method. A core limitation is that the cutters dictate the size and shape of the cut path. So if you are doing tight internal corners, the radius of the cutter becomes a limiting factor. Also thin cutters, are prone to breaking, especially in dense or hard materials. This makes fine detail work hard to accomplish and time consuming in the very least.

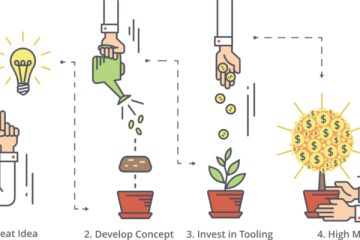

Another drawback to CNC machining is that you need to program a cutting path that the computer-controlled head will follow. This means new products will have a one off additional cost, for someone to sit down and figure out the best program for the desired cut path. Milling and Machining is generally a time-consuming process, and therefore it is best suited to one-off pieces or small batch production runs. Finally, you are generally restricted to size of stock material blocks. If your part is just too large for a stock size or only takes up a fraction of the smallest size on offer, you must buy the larger stocked size. This is then hammered home, as you will tend to waste the majority of the material that you are forced to buy.

If you need a part machined, or if you have a product idea, and you’re not sure how to make it, come and talk to us about a free 1-hour meeting.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox