We often get asked, are all steels the same? In fact, it’s one of our frequently asked questions.

The short answer (and the one featured in our FAQs) is – No, there are different grades and hardness of steels. Hard steels tend to last longer but are more difficult to machine and heat treat.

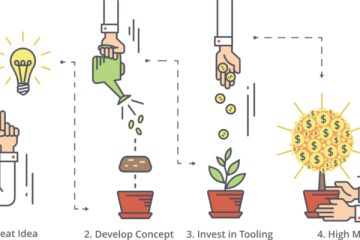

But let’s break it down further and look at the main types of steel and their grades and properties. Knowing a little more about your steel options can help you make a better informed decision about your part, mould or tool.

Steel is a catch-all phrase used to describe a group of iron alloys. All steels are composed of iron and carbon. It is the amount of carbon, and any additional alloys that determine the properties of each grade.

Steel can be broadly categorised into four groups based on their chemical compositions:

– Carbon Steels

– Alloy Steels

– Stainless Steels

– Tool Steels

Let’s take a closer look at their properties…

Carbon Steels:

A carbon steel has a carbon content of up to 2.1% by weight. As the amount of carbon content rises, the steel will become harder and stronger through heat treating. While this means that carbon steels are incredibly durable and impact resistant, they also become less and less ductile.

The higher the carbon content also means the weldability of the steel in reduced, as the high carbon content leads to a lower melting point of the steel.

Alloy Steels:

Alloy steels are broken down into two groups: low alloy steels and high alloy steels. This refers to the amount of alloying elements added (like manganese, silicon, nickel, titanium, copper, chromium, and aluminum).

All steels are technically an alloy, but not all steels are called “alloy steels”. A basic steel is made of iron alloyed with carbon, but “alloy steels” refers to steels containing other alloying elements in addition to the carbon.

The addition of different elements produces different properties in the steel, for example copper increases corrosion resistance, while silicon can improve magnetic properties.

Stainless Steels:

Stainless steels are called as such because the alloying properties make it incredibly corrosion resistant. It is classified as containing a minimum of 11% chromium content by mass and a maximum of 1.2% carbon by mass.

The properties of resistance to corrosion and staining, low maintenance, and familiar luster make stainless steel a popular choice for commercial applications.

Tool Steels:

Tool steels have their own category because they are a collection of steels that have particular properties making them ideal for use in making tools.

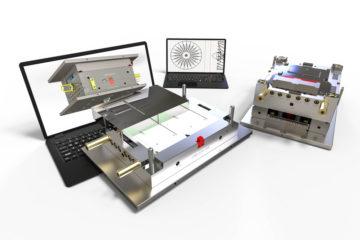

We’re well versed with tool steels, we’ve actually talked about some of the tool steel grades we use here at Dienamics in our blog Let’s Talk About Tool Steel.

When it comes to tooling and mass production, choosing the right steel for the job is incredibly important. If you’re still not sure what steel suits your needs or if you’re in need of a new tool, we can help. Get in touch with us today.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox