Thinking of getting your product manufactured? If so, choosing the right material for your product is an important decision that can impact its success.

The material that you choose impacts not only your product’s performance and durability, but also its aesthetics and cost. There are many factors that go into choosing the right material, and the list of potential materials is endless. If you’re not sure which material will suit your product best, don’t worry you are not alone – this can often be one of the most overwhelming parts of the design process, which is why we are here to help! In this article, we’re sharing our six tips for choosing the right material, informed by our years of experience in product manufacturing.

1. Understand Your Product’s Requirements

Before diving into material selection, it is essential to thoroughly understand your product’s requirements. Think about what you need your product to do, and the conditions you’ll need it to work in. For example, you should consider your product’s:

- Functionality

- Desired lifespan

- Environmental conditions

- Regulatory compliance

- Load-bearing capacity

- Resistance to wear and tear

- Chemical compatibility

Once you have considered these factors, you should then research the specific certifications or industry standards that your product must meet. For example, does it need to be resistant to heat/cold, safe for food handling, or safe for children to use? The more you understand about your product’s requirements, the easier it will be to choose the right material.

2. Assess Material Properties

Next, you’ll want to assess the physical properties of each material that’s available to you. Take the time to research different materials and analyse both their aesthetic features and functionality. Take a look at the material’s unique qualities, such as:

- Strength and stiffness

- Flexibility

- Weight

- Density

- Transparency

- Thermal conductivity

- Resistance to corrosion, moisture, heat, and chemicals

By carefully assessing these properties, you can narrow down your options to materials that align with your product’s requirements.

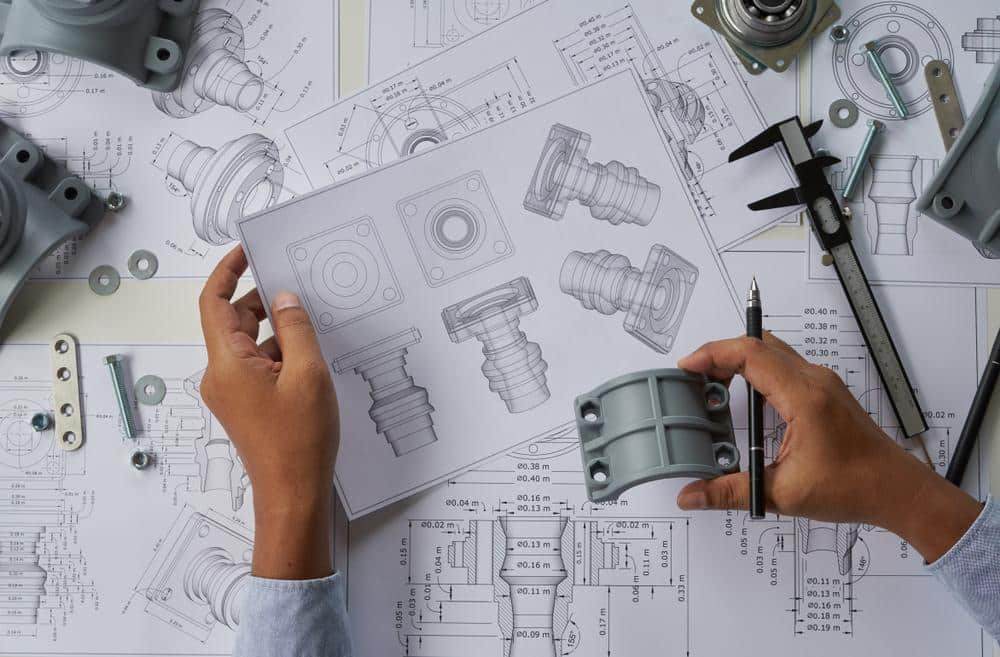

3. Evaluate Manufacturing Processes

Next, you’ll want to consider the manufacturing process that will be involved in creating your product. For example, different materials will require specific manufacturing techniques, such as moulding, casting, or machining. This can have an impact on the production cost, time, and complexity of your project. If you’re unsure, we recommend taking the time to analyse the compatibility between your chosen material and its manufacturing process to ensure a smooth production. This will help you to avoid any potential issues or delays.

4. Consider Cost and Availability

Another important factor to consider when choosing your material is the cost. It’s a good idea to compare the prices of different materials and evaluate their long-term cost-effectiveness. When thinking about cost, keep in mind that the supply and demand of each material can change over time, influencing its price. Scarcity or limited availability can lead to increased costs and potential supply chain issues. If you can, try to strike a balance between material quality, cost, and availability to ensure an efficient production process and maintain your project’s profitability.

5. Test and Prototype

Once you have narrowed down your material options, it is crucial to test and prototype your product using those materials. This step allows you to assess how the materials perform under real-world conditions and whether they meet your expectations. Prototyping helps uncover any design flaws, manufacturing challenges, or limitations associated with the selected materials. Through testing and iteration, you can fine-tune your material selection and ensure the final product meets the desired standards.

6. Seek Expert Advice

If you’re still unsure which material is best for your product, talk to us! We have a team of in-house industrial designers and manufacturers who can provide tailored advice on your project. We will make recommendations based on our years of experience in the design industry, and help you make the best choice that aligns with your product’s requirements and goals.

Summing Up

Selecting the right material for manufacturing your product is a critical decision that requires careful consideration. By understanding your product’s requirements, evaluating manufacturing processes, considering costs, and testing prototypes, you can make an informed choice. The right material will enhance the performance, durability, aesthetics, and cost-effectiveness of your product, ultimately contributing to its success in the market.

Looking to get your product manufactured?

At Dienamics, we have over 35 years of experience in industrial design, product design, tool making and manufacturing in Brisbane. We offer specialised design services to help you take your concept from an idea to a reality.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox