If you’re in the process of designing and developing your product, then rapid prototyping might be an option for you.

Rapid prototyping is a quick way to create a physical part from a computer design. It gives you an idea of what your final product will be like and allows you to quickly evaluate your product.

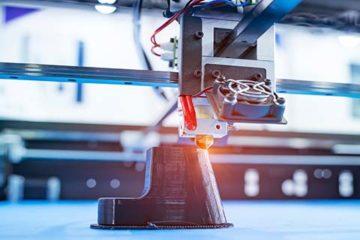

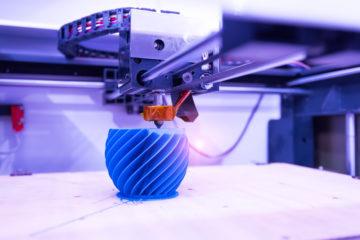

RP uses a variety of manufacturing techniques to create parts including high-speed machining, casting, moulding and extruding. For product designers, RP is useful for aiding in visualisation, design, development and manufacturing of a product before mass production.

How does it work?

There are three main steps in the rapid prototyping process. First, you create the prototype for the product. It can be either high fidelity, meaning it closely resembles the finished product, or low fidelity, meaning it is made from different materials or simplified.

The next step is to review it. Share the prototype with your customers, colleagues or stakeholders. Ask for feedback so that you can find ways to improve your product and minimise errors.

The final step is to refine it. Based on the feedback you receive, you can implement changes to your product to ensure it better serves your customers’ needs. Once you are satisfied with your prototype, you can start to manufacture your product and then deliver it to your customers.

Why use Rapid Prototyping?

Rapid prototyping can bring many benefits to you as a designer. If you use rapid prototyping for your product, you can:

● Gain a more complete picture of how your product will look

● Implement changes

● Solve problems

● Save time and improve efficiency

● Automate the prototyping process

● Reduce material wastage

● Reduce errors in manufacturing

● Provide greater choice and flexibility to your customers

How much does it cost?

The price of rapid prototyping depends on the volume and size of the parts, the surface finish, the type of materials, and how much post manufacture processing is required.

RP has a higher initial cost than other forms of prototyping. However, it can help you to iron out issues in your product early, which will help to streamline your manufacturing process. This way, RP saves you money in the long run.

When is it the best option?

Rapid prototyping is the best option for developing your product when you want:

● A fast and simple prototype

● To test your product thoroughly

● To improve your user experience

While RP is an excellent way to develop a product, there are some times when it won’t be the best option. These include when you want to:

● Make an accurate model

● Test a complex product

● Save money upfront

● Use specialised materials

If you’re wondering if rapid prototyping is the right option for you or would like more advice, talk to the team at Dienamics.

Looking to get your product prototyped?

At Dienamics, we have over 30 years of experience in industrial design, tool making and manufacturing in Brisbane. We offer specialised prototyping services to help you take your concept from an idea to a reality.

If you think prototyping will help you to develop your product, then give us a call. Talk to our expert team today.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox