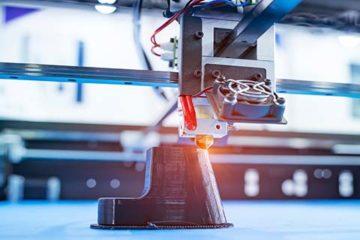

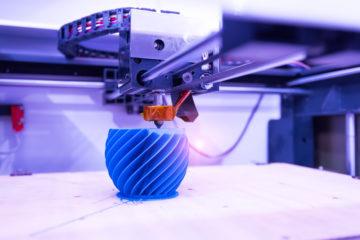

Rapid prototyping technology has been used to create components and tools for a robot astronaut on the International Space Station (ISS). Prototypes manufactured from selective laser sintering (SLS) were used to test tool bodies, adapters and end effectors.

The final components were then manufactured from steel or aluminium before being installed in NASA’s Robotic Refuelling Mission (RRM) module. The RRM has now been attached to the Canadian Space Agency’s (CSA) maintenance robot Dextre, according to Machine Design.

The module and fitting was a joint project by the Canadian Space Agency and NASA engineers. The modules have allowed the CSA and the ISS to demonstrate how robots can be used to service and refuel satellites. Dextre has already used some of the rapid-prototyping modules in refuelling-, repairing- and repositioning-associated exercises on the ISS.

Solid Concepts Inc., a California-based rapid-prototyping company, provided mechanical linkages and frames for various parts of the module. SLS was chosen to create the prototypes, as the process supported the creation of fine-featured particles from different materials.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox