Are you in the process of designing and developing your product? If so, you may be looking for a way to test and preview your product’s function, aesthetics, or physical properties. The most effective way to do this is through rapid prototyping.

If you’re considering rapid prototyping your product, then you’ve come to the right place. In this article, we’re exploring all you need to know about rapid prototyping and diving into the benefits of this process.

What is rapid prototyping?

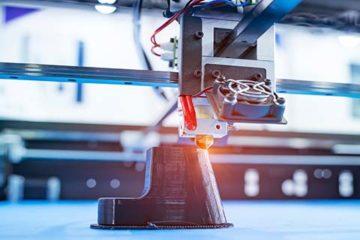

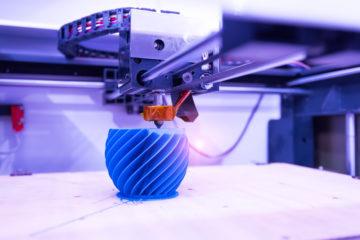

Rapid prototyping (RP) quickly creates a physical part directly from its CAD model data using various manufacturing techniques such as CNC machining and 3D Printing.

RP can be used at any stage of the product development cycle. It can be repeated numerous times along the new product design process using the test data to refine the product’s design and achieve the desired result.

Through RP, you can quickly assess the visuals and functionality of your product and make informed decisions about how it will serve your end-users or feasibility of manufacturing.

Why is rapid prototyping important?

In today’s fast-paced consumer market, companies need to develop and introduce new products faster to remain competitive. This pressure to develop new products faster means that innovative processes like RP are becoming more important.

With RP, companies can achieve objectives such as streamlined production and faster time to market. It also allows for functionality testing and can be used to gain hands-on feedback from your end-users. Perhaps most importantly, it is the best way to avoid putting out a faulty products that let down customers – all too many times have we all seen faulty products out there that have tarnished a company’s reputation. Just think of car manufacturers with car faults, that leaky water bottle that you’ll never buy again, or that pair of headphones that broke after 2 months. Of course, sometimes products are designed to be cheap and replaceable, though at other times it is simply design oversight, and this is where rapid prototyping is absolutely crucial.

Pros and Cons of rapid prototyping

Rapid prototyping has its advantages and disadvantages, like any manufacturing process. Here are some of the benefits:

- Reduced design and development time

- Reduced overall product development cost

- Elimination or reduction of risk

- Allows functionality testing at a fraction of the cost

- Improved and increased user involvement during design stages

- Ability to evaluate human factors and ergonomics

- Allows for design changes to optimise manufacturing and assembly feasibility – reducing production costs

Now, let’s take a look at the disadvantages of rapid prototyping:

- Added initial costs

- Some rapid prototyping processes are still expensive and not economical

- Reduced material properties like surface finish and strength

- Requires skilled labour

- A more limited material range

- No prototype will be fully identical to the final product unless made with the same materials and manufacturing method

Even though there are some disadvantages in RP such as the higher initial cost, it can save you time, money and your business’ reputation in the long run. If you’re unsure whether rapid prototyping is the best option for your product, or just need some advice, talk to us!

Looking to design your product?

At Dienamics, we have over 35 years of experience in industrial design, tool making and manufacturing in Brisbane. We offer specialised manufacturing services to help you take your concept from an idea to a reality.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox