Part 2 – Things You Need to Understand Before You Prototype:

1. You need to budget for it, you need to make sure you’ve got sufficient funds and enough time set aside so that you don’t rush any prototyping or testing

2. You also need to develop a clear understanding of why you are prototyping and what you want to get out of that prototype

3. And you need to understand that prototypes are to check, prove and find faults

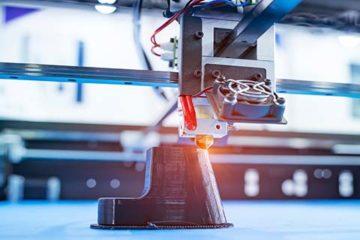

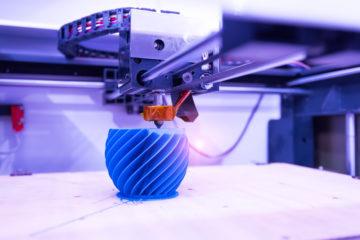

1/ Understand the budget – depending on what you are looking for in the outcomes of the prototype will depend on your budget. Your first prototype is maybe just to check the concept design so you can feel confident in moving ahead with more involved designs. Or it may be to test the design and check the CAD work before making multiple prototypes for field testing. So, you may start off with a 3D printed or SLS prototype but for your final you may do Vac cast or CNC prototypes.

2/ What do you want the prototype for? Is it non-functioning for display or sales? Is it to test a design and check the CAD work?

If you’re wanting to test the mechanical properties of the design, you would have to prototype using the same material, or as close to it as possible. Be clear of what you are after, all designers will prototype to test the CAD work and the functionality of the design; this will be our first priority. Sales and marketing are something that we won’t be concerned about unless the customer specifically requests this in the prototype. Even if they do, the first rounds of prototypes will more than likely still focus on the design and function of the prototype; designers are always trained to prove the design before sales or marketing is addressed.

3/ People often rush the prototyping stage because once they have the CAD designs done or what they think is completed, they become eager to get to tooling and begin producing products for consumers. Customers can sometimes get upset or frustrated if the prototypes has highlighted issues. Understand that if the prototype picks up mistakes, design issues or other failures, this does not mean that the prototype was a failure. In fact, it is the complete opposite, the prototype has been a success as it has done its job and found issues before costly tooling is built. Most customers need to prototype several times to prove a design & you need to understand this before you begin the process. If designs and CAD data could be guaranteed to be correct before prototyping, we wouldn’t need prototyping or an R&D (Research and Development) industry.

In the next installment of this series we’ll take a look at the various types of prototypes there are, how they are used in different stages of the design process and what types we use at Dienamics to help you reach your goal of developing your product idea.

Missed the first part of our prototyping knowledge series? You can find it here: Introduction to Prototyping.

Sign up below to receive the next issues in our series straight to your inbox.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox