The first time you even here of this concept it is easy to think of some form of 3 dimensional image printed onto a glossy page. This is further from the truth. With a mulititude of uses, from making prototypes to creating detailed casts for plastic injection moulding, 3D printing is big, it is real and it is very available. A look at what it is and how we can do it…

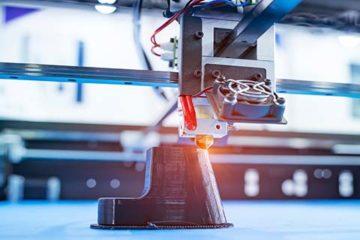

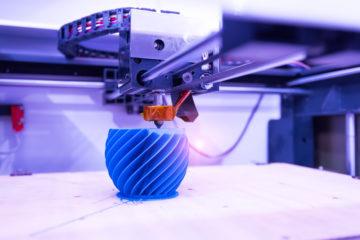

The basics. It is a form of printing, just like a printer that you use at home, but instead of printing letters of ink onto paper, it prints layers often made of liquids that cure, or soften plastics that harden, onto a base. An object is created instantly before your eyes as the tiny layers are built up as an exact tangible rendering of the 3 dimensional image in the software of the computer. One method of 3D printing is actually very similar to the ink-jet printer that you use at home. It sprays layers of a resin that harden under normal light in a short period of time to create an object. Remember that we are talking minute thickness and so even rounded shapes can be created.

Efficiency. 3D printing is an excellent and efficient way to make prototypes in a very small amount of time. When you compare some of the out-dated modes of making prototypes with the speedy process of 3D printing, the benefits are enormous. Many companies large and small are finding out exactly how their new products will be much faster and much cheaper that ever before. With knowledge of software packages that integrate you can take product design to model product in one step. The savings from idea to reality are enormous. Costly mistakes are avoided.

Uses. Is used in a variety of industries and the uses are limitless. You can create the look and that all important feel in your hand of what a product will be like way before you go into the production process. Because of the flexible applicability of this process, we are seeing it used in more and more industries. It has been used industrial design, architecture, automotive, dental, engineering and aerospace for some time (just to mention a few). Recently it has also expanded into jewellery and even footwear. There seems to be no limit to its uses.

Cost and expansion. Since around 2003 the cost of 3D printers has rapidly reduced to a reduction of production costs and the wide usage in the market place. From when they were first invented in the 1990s, until they became even available for small business use by companies who are specialists in mass production of printers we already know. With the expansion of user friendly software packages this has made it all the more easier. The cheapest models are still around 20,000 dollars and designed to be used in shared environments but don’t be surprised to find one available for home or small business use as the technologies become cheaper and safer.

3D printing is a real, practical and efficient way to generate your idea into reality, and it is very affordable and here to stay.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox