When it comes to developing your product, prototyping is a crucial part of the process.

Unfortunately, creating a prototype can be slow and painful without the right technology, and can significantly slow down the design process.

With 3D print prototyping, you can streamline the prototyping stage to get your product on the market fast.

What Is 3D Print Prototyping?

3D print prototyping combines rapid prototyping with 3D printing so that you can quickly and accurately create a prototype of your product.

With this method of prototyping, you can create a 3D model of your product that’ll allow you to effectively test, evaluate, and identify areas of improvement.

While there are some distinct differences between rapid prototyping and 3D printing, 3D print prototyping has a myriad of benefits that will enhance the design and development of your product.

The Advantages of 3D Print Prototyping

Quick Turnaround Times

At Dienamics, we can usually deliver you a 3D printed prototype in less than a week, provided that you have a CAD model.

For a more complex, highly aesthetic model, the turnaround time is generally two weeks.

Quicker creation times mean you have more time to make the adjustments and do the product testing you need to do.

Less Expensive

Due to the rapid turnaround time for the prototype, you’ll save money by saving time.

As the prototype won’t need multiple different machines to be made, this will also save you on labour and machine costs.

Smoother Workflows With CAD

Using this new technology means smarter processes. If you have your design as a CAD file, you can upload it to a 3D printer, and then the machine will read it and produce the prototype…

This way, you don’t have to program other tools or use manual workflows to do the job, eliminating much of the work and time spent making prototypes in more traditional methods, like subtractive prototyping.

CAD and 3D printing have made producing prototypes increasingly accessible, without the need for huge investments into large specialised equipment, like CNC milling machines, although, 3D printing does have its comparative downsides to other processes.

More Material Options

With 3D printing, there is a lot of flexibility with the material you choose to make your prototype. Materials you can use include:

- ABS

- ASA

- PC

- PC-ABS

- PLA

- PETG thermoplastic

- Nylon

- TPU

Run Tests Easily

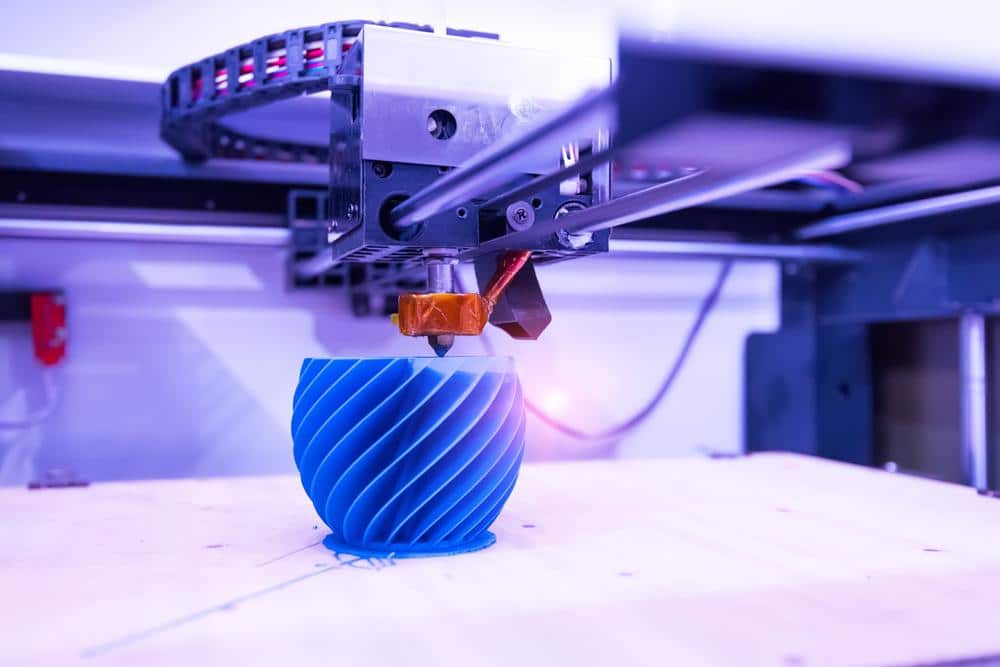

Depending on the design, 3D printed prototypes can be mechanically functional, aesthetic, or mostly functional prototypes.

This means that most of the time you can test designs quickly and with a great deal of feedback, allowing you to implement necessary design changes inexpensively and easily.

3D print prototyping offers you a way to gather in-depth data and feedback from future product users without breaking the bank.

Need A 3D Printed Prototype?

If you have a marketable idea that is ready to be tested and turned into a product, prototyping is a step you can’t miss.

Dienamics has you covered for all of your Product Development & Prototyping needs.

For rapid or 3D print prototyping that is right for your product, talk to our team to see how we can help you.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox