Part 3 – Types of Prototypes

In Part 2. ‘Before You Prototype‘, we looked at the importance of developing a clear understanding of why you are prototyping and what you’re wanting to achieve from it. In this issue, we’ll list some of the different types of prototypes and their purpose; we’ll go into depth on each one in later issues.

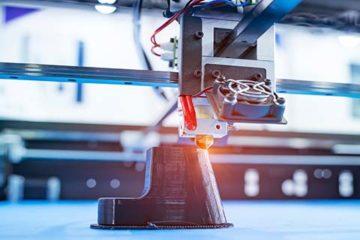

SLS 3D Printing

Selective Laser Sintering or SLS is a 3D printing technique that works to build a 3D object by sintering fine layers of material powder together.

- Unlike traditional 3D printing methods, support structure does not need to be removed post-print

- Rapid process

- Offers a low-medium finish quality

- Used for small, unique and complex design

- Few days to make

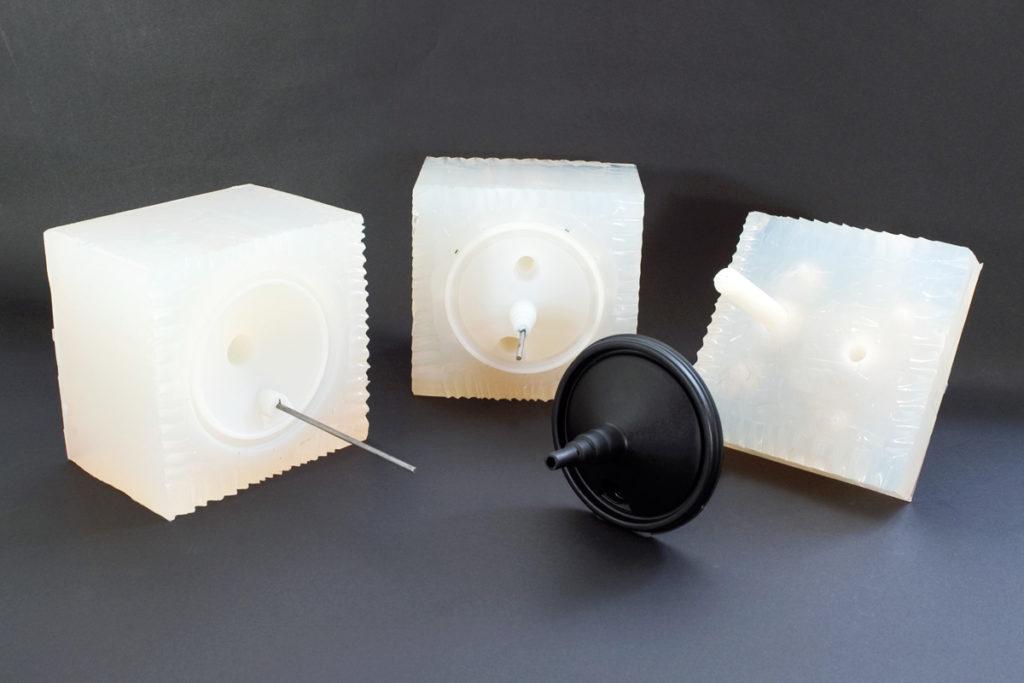

Vacuum Casting

A master model is made to create a mould. Plastic resin is drawn by vacuum into the mould to make a copy.

- Up to 25 copies can be made from the single mould (depending on the moulds complexity and material used)

- Price of mould spreads thinner the more copies you manufacture

- Surface quality comparable to injection moulding

- Few weeks to make and produce copies

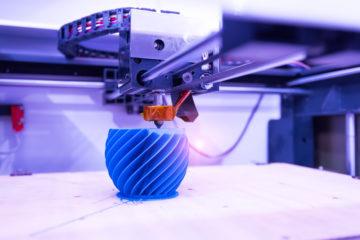

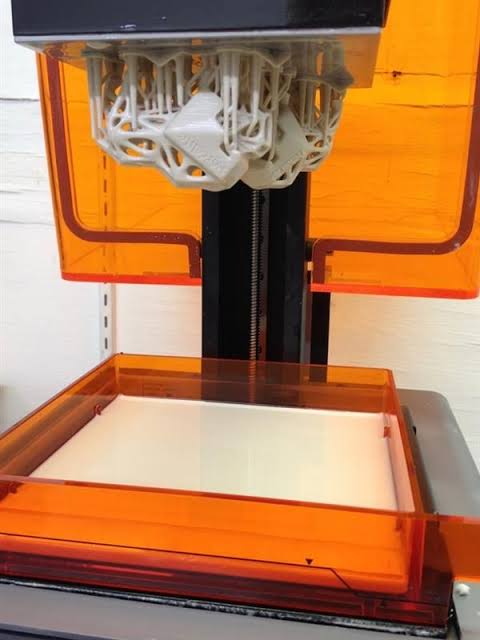

SLA & FDM 3D Printing

Stereolithography (SLA) & Fused Deposition Modelling (FDM) are the two most common 3D printing technologies. FDM works by heating and extruding plastic filament. SLA works by selectively hardening plastic in a resin basin with ultraviolet light.

- For prototyping small components

- Poor mechanical properties

- Comparatively cheap processes

- Few days to make

CNC Machining

Prototype is formed by cutting away from a block of material using a computer controlled spindle with cutting tool attachments.

- High dimensional accuracy

- High surface finish

- Choice of materials (plastics, metal wood, etc. all suitable)

- Week to two weeks to make

Part 4. of this Prototyping Series will look deeper into the importance of conducting user research and testing with your prototypes.

We’ve got over 30 consecutive years’ experience in the design and manufacturing industry at Dienamics, so please feel free to call or email if you have any queries or questions about a product idea you’re keen to get off the ground!

Haven’t signed up to the Prototyping Series yet? Subscribe below to receive the next issues in your inbox every Wednesday!

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox