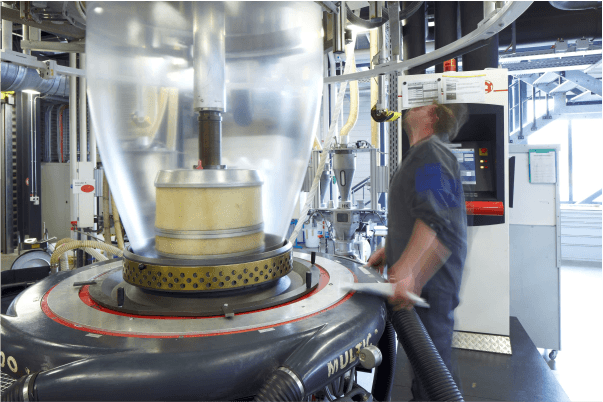

Blown Film is a manufacturing process that produce films of plastic sheeting and tubes. These sheets or tubes can either be fully cylindrical, or have other object inserted into them so they form useful objects like shopping bags, rubbish bags or cling wrap. In this article, we will explore what the process of blown film is and how and why you would use it.

The process of blown film is reasonably simple. First you must take plastic pellets and heat them to their melting point (like injection moulding). The plastic is then forced through a cylindrical die and forms a thin walled bubble. This bubble is sustained by air, and is fed up through a scaffold where the tube continues to rise. Over this length, the plastic begins to cool. Once it has cooled enough, it is collapsed down on itself, forming a flattened tube. This tube is passed through various rollers and spun onto a spool. The edges of the tube can be trimmed and it can also be punched, cut or printed on before going on the spool.

Blown film manufacturing is great for producing products that require uniform properties along the length and width of the product. It’s also a great high volume production method, however it requires massive capital cost to purchase a blown film machine. Blown film can produce up to 130 metres of products in a single minute. The sheets and film they can produce can be as fine as 10-20 microns (0.01mm – 0.02mm) to 250 microns (0.25mm) thick. Most Blown film is either High or Low Density Polyethylene (HDPE or LDPE) but there are exceptions. The downside to blown film is that it can only product sheets or tubes. If you’d like to know a little more about Blown Film, contact us and our friendly design team will help explain the process a little more.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox