Plastic products are all around us in our daily lives. Have you ever wondered what it would be like to live without plastic products?

The future of plastic manufacturing seems hazy, given all of the environmental concerns about plastic. Many people are trying to move away from traditional plastics in search of more sustainable alternatives.

So, what does the future of plastic manufacturing look like?

While we don’t have a crystal ball that can predict how we will handle plastics in the future, we can tell you about what we can do with plastic to enhance the future of the plastics industry.

Plastic Features

Plastics have some hidden features that you may not be aware of. For instance, certain plastic polymers will absorb water and moisture to make themselves stronger and less brittle. During the Moulding process, plastics will shrink to a certain extent but some plastics can also expand after production depending on the temperature and environmental impacts. We have plastics that we can develop to be best in the sun, fire-resistant or block electronic signals.

Enhanced Plastics

New plastics are being developed that combine nanotechnology with plastic engineering. These are enhanced at the molecular level. Their useful features include dimensional stability, flame and heat resistance, electrical conductivity, and resistance to scratches and dents.

They have been used in the aerospace and automotive industries, as well as in food packaging, military equipment, electronics, and more.

Radio Frequency Embedded Plastics

Injection moulding gives us the ability to Overmould RIFD tags or other radio frequency devices into the plastic while the product is being produced. They are used in highway toll tags, clothing tags, hospital patient tracking, security system badges, cargo container seals, and many more industries.

Recycled Plastics

Using recycled plastics is an important step in looking into the future of the plastics industry. Many big companies have already made the move to use recycled plastic in the production of their products. Recycling plastics can be as simple as regrinding up any rejected parts or sprue of the parts and regrinding them to mix back in during the production run.

Here at Dienamics we encourage the use of recycled plastics and have been moulding with recycled plastic for the majority of our projects for over 20 years.

Bioplastics

Bioplastics have an important role to play in the search for more eco-friendly plastics. They are based on resins from plants and are a greener option for plastics. They have been used in aerospace, electronics, automotive, and telecommunications industries so far. Plastics that can decompose with the help of bacteria are also being developed.

Plastic is a necessity of modern life but the days of single-use plastics are coming to an end. As the world becomes more aware of our environmental impact, it is important that we too evolve and come up with ways to reduce our environmental impact.

Here at Dienamics, we have taken many steps, including using recycled materials, not moulding single-use and installing solar panels to name just a few, to make sure we are doing our part.

Looking To Get Your Product Manufactured?

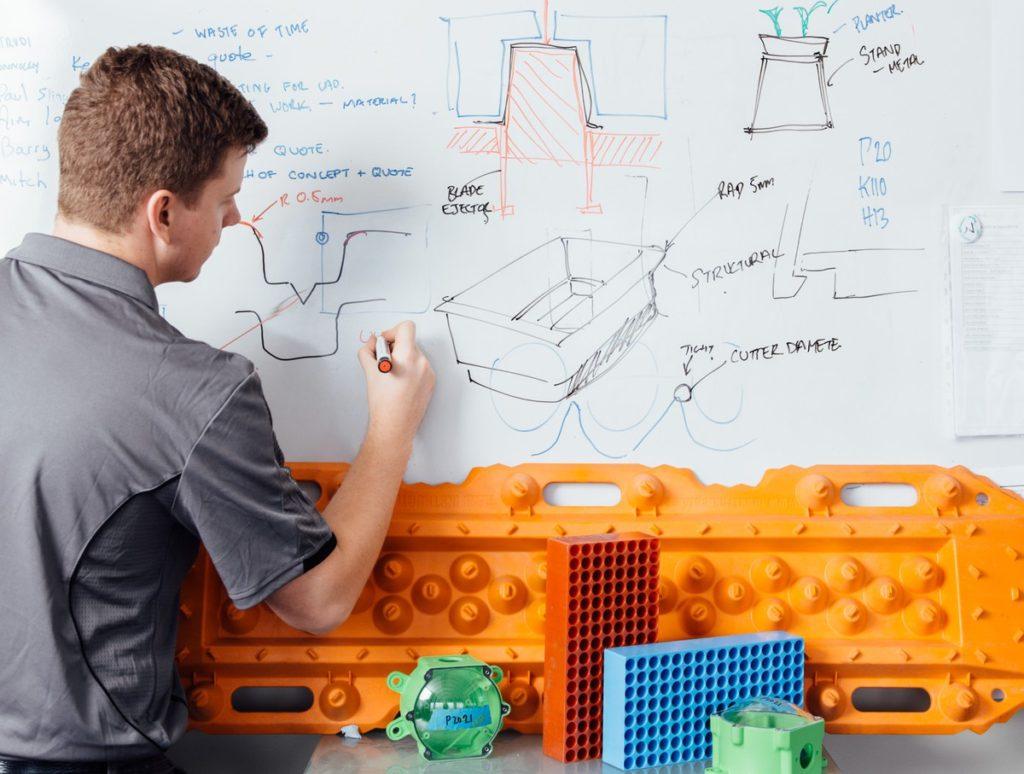

At Dienamics, we have over 30 years of experience in industrial design, tool making and manufacturing in Brisbane. We offer specialised manufacturing services to help you take your concept from an idea to a reality.

If you need help manufacturing your product, then give us a call. Talk to our expert team today.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox