Have you ever gotten an injection? A flu shot? A vaccine? Anaesthetic? If the answer is yes then it’s almost guaranteed that a plastic injection moulded syringe was used.

With plastic manufacturing becoming more reliable after WW2, the use of plastics in consumables began to become common practice, and with this even more progress to the manufacturing techniques and materials followed. During the 1950s, plastics started replacing other materials in order to make products cheaper and occasionally better. This revolutionised the manufacturing industry. Plastics were used as a strong, but more importantly, cheap material that could be mass manufactured. With this came a boom of new revolutionary products that helped change the world. Just one example of this is the plastic syringe.

The Plastic Syringe

With syringes being metal during WW1 and partially glass during the end of WW2, the plastic syringe was a cheaper, faster to manufacture and more hygienic option that made medical supplies such as flu shots and vaccines far more accessible and inexpensive.

During WW2, syringes became common medical instruments that were used to administer morphine, penicillin and other medicines to injured or ill soldiers. This method of injecting medicine was superior to consuming pills due to the effects occurring in a fraction of the time and being safer on organs. Unfortunately, the syringes being used were expensive metal instruments that were sterilised and reused via a flame to the needle. This was problematic due to unfavourable hygiene outcomes and the occasional spread of infection or illness if not cleaned effectively. In 1949, an Australian inventor named Charles Rothauser created the world’s first plastic disposable syringe in Adelaide and in 1951, millions of these polypropylene syringes were being made for Australian and export markets. These disposable syringes changed the medical industry and health outcomes for people around the world, making medicine more accessible but also far cheaper.

Producing a product with plastic lends real power and potential to a device that may already be life-changing. Due to the fact that it is an incredibly diverse and inexpensive material, products made with plastic can be produced for the masses with ease compared to other materials.

For more information about the history of injection moulding make sure you click here.

At Dienamics, we offer a range of comprehensive services in every step of the product manufacturing process. These include:

- Product design, including concept assessment and project scoping

- Prototyping and process and materials testing

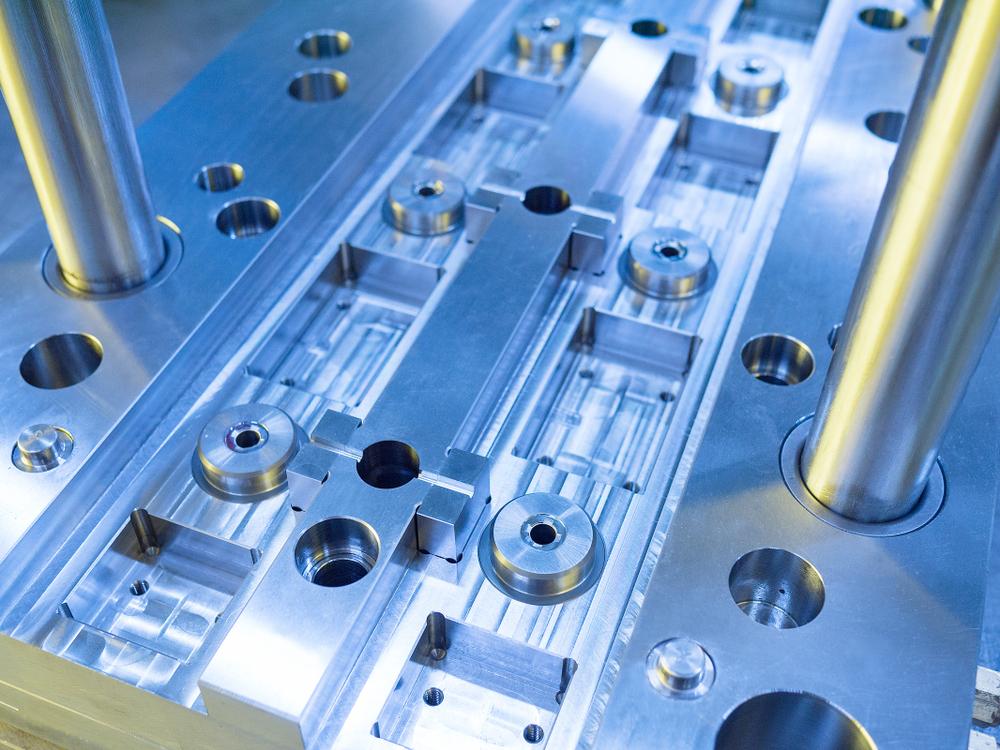

- Manufacturing, injection moulding, production, assembly, and packaging

Contact us today if you have a product you’re looking to get designed & manufactured!

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox