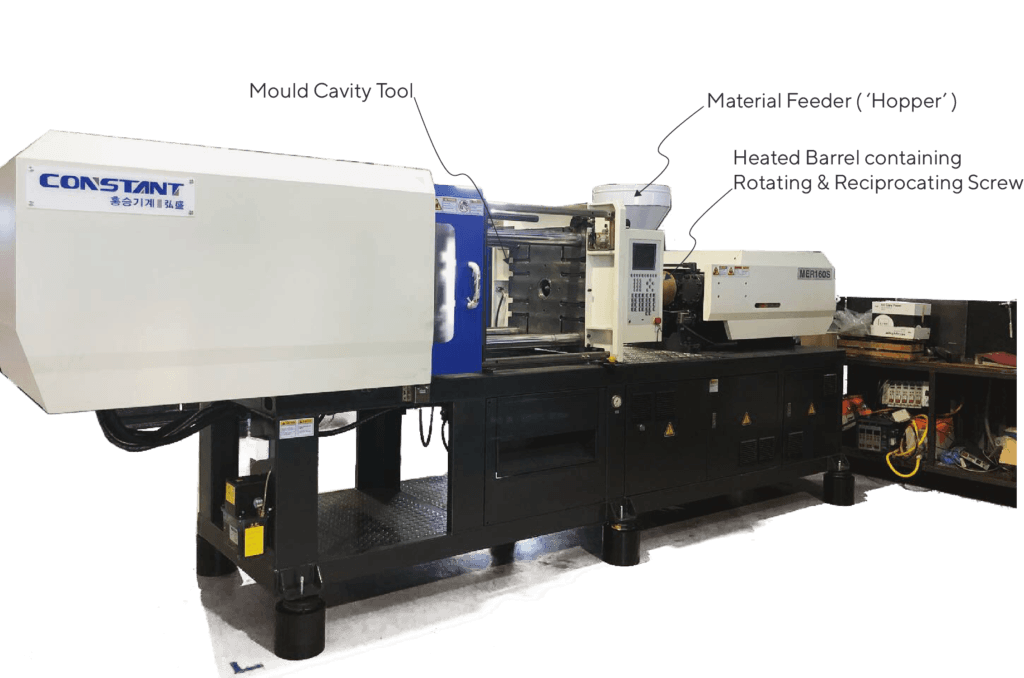

Plastic injection moulding is by far the most popular method for producing mass manufactured plastic products – though if you’re new to the design and manufacturing game, here’s a quick recap. An injection moulding machine has a few main elements; a material feeder, called a ‘hopper,’ where plastic granules are poured; a heated barrel that melts the granules down; a rotating and reciprocating screw that mixes the molten plastic and creates the pressure needed for injection; and finally a steel injection mould cavity tool which is made to take on the shape of your final product.

When it comes to manufacturing, it is one of the more desirable methods due to its simplicity and ease of process. If you’re well acquainted with the process, you will have seen the results and shouldn’t have any doubts about whether or not plastic injection moulding is the right method for your product design. But, just in case you do, here are 5 amazing benefits of plastic injection moulding that will surely convert you.

1. It’s Cost Effective

One of the most appealing benefits of plastic injection moulding is that it’s economical. Because most of the process is automated, manufacturing costs and overheads are significantly reduced. Don’t get it wrong, though, that doesn’t mean it cuts corners – automation allows for more precise and accurate plastic injection moulds, if anything. Computer aided design (CAD) and computer aided manufacturing (CAM) are the features of this process that drive accuracy.

2. It’s Fast

For a start – it’s fast. How fast you, say? Plastic Injection Moulding generally only takes around 15 to 30 seconds between cycle times (although this can depend on the complexity of the part). Thousands of parts can be manufactured from a single mould, and this high production output is yet another feature of the process’s cost effectiveness.

3. It’s Reliable

Plastic injection moulding offers the choice to use fillers, which reduces the density of the plastic but also adds greater strength to the part after it has been moulded. This is an option that other moulding processes do not offer, which makes it an ideal process for industries or products where parts need to be durable and strong.

4. It’s Sustainable

More and more, product developers (and the rest of us) are becoming aware of factors in product design that both benefit the environment and minimize waste. Plastic injection moulding is sustainable for both the user and the planet because it only uses as much plastic as necessary to create the part. Not only that, but if there is any excess plastic, this can easily be ground up and recycled after use.

5. It’s Adaptable

Multiple plastics? No worries! Co-injection moulding can me used for multiple plastics, which takes away the stress of having to be specific. Co-injection moulding machines are designed especially to bring together different types of plastics to produce your desired end product with accuracy, so you won’t be sacrificing any of the benefits of injecting with one particular type of plastic.

Plastic injection moulding is one of the most popular processes for producing plastic parts, and with good reason. If you would like to have a chat about injection moulding for your part, book a free consultation with us today!

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox