Here at Dienamics, we have been pushing carbon neutral practices through the use of multiple new technologies. It is our goal to become carbon neutral and we have invested time and money into new technologies and strategies in an effort to become more eco friendly.

This year, we have invested in more solar panels for clean energy. The entire roof of our workshop is now covered in solar panels, contributing over 70 % of our total energy usage. These panels also put any extra unused energy we generate back into the grid. Along with this, we have invested in energy efficient moulding machines that dramatically lower the amount of energy we consume.

As a company, we do not manufacture single use plastic products, and we specialize in designing plastic products that will be used for a long time. Plastic products are a necessity in our modern world, but we can design products to have a smaller impact on our eco footprint. On several products, such as Max Trax and Reo Bar Chairs, we have been able to redesign the product from its first design to reduce the plastic needed to mould the part, while also keeping the strength of the part. In most instances, we have even increased the strength of the product.

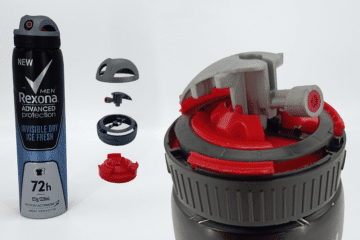

We keep wastage and energy consumption of manufacturing our product in mind when designing and tooling the product. Because of this, we tend to analyze if a hot runner system or a cold runner system would be more beneficial to the customer. A hot runner system has no plastic or very limited plastic when moulding a part, while a cold runner system has a ‘sprue’ that needs to be recycled otherwise, it is a substantial waste. Sometimes, cold-runner tools can be cheaper or more beneficial to the product, so we have invested in new technologies to continue to recycle and reduce wastage, even if we cannot do it with a hot runner system.

Here at Dienamics, we only use thermoplastics. This means that any product we create can be re-melted, and if done in-house, can be reground and reused. Sprue pickers help recycle any unused sprues (excess plastic) from the manufacturing stage and move them from the successful product line. Regrinders chop up the sprues and unwanted products so they can be melted and recycled. New vacuum systems suck the reground plastic granules from the regrinders and mix them with the material in the injection moulding machines to ensure maximum recycling in an automated circular process. Through the use of these new technologies, we minimize our wastage and ensure that we use 100% of our product. Along with this system, we also mould some products from 100% recycled material.

Because we offer all stages of the product design process under one roof, we can guarantee that the sustainability of your products will be kept in mind throughout all stages. We follow a clean process and maximize productivity while minimizing waste. We are also continuously improving our manufacturing techniques and processes to ensure that we stay ahead of the competition with our eco friendly processes.

We have been taking our carbon footprint very seriously and will continue to invest in reducing wastage and energy consumption wherever we can. For more information on how we design to make sustainable products, make sure to read our blog 3 Ways Product Design Creates Sustainable Manufacturing.

At Dienamics, we offer a range of comprehensive services in every step of the product manufacturing process. These include:

- Product design, including concept assessment and project scoping

- Prototyping and process and materials testing

- Manufacturing, injection moulding, production, assembly, and packaging

Contact us today if you have a product you’re looking to get designed & manufacture!

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox