Product deconstructions are one of the best ways to learn about what makes a design good or bad. If you can pull a product apart, analyse it for its’ clips, fits, interferences, and manufacturing processes – you can start to understand why products are designed the way they are, which in turn, teaches you how to design your own products well.

Product deconstructions are one of the best ways to learn about what makes a design good or bad. If you can pull a product apart, analyse it for its’ clips, fits, interferences, and manufacturing processes – you can start to understand why products are designed the way they are, which in turn, teaches you how to design your own products well.

We used the Rexona Spray Can as an example for this review, just to show you how much thought, effort and ingenuity goes behind the simplest products, and designing products well for manufacturing!

Rexona Can Component Deconstruction

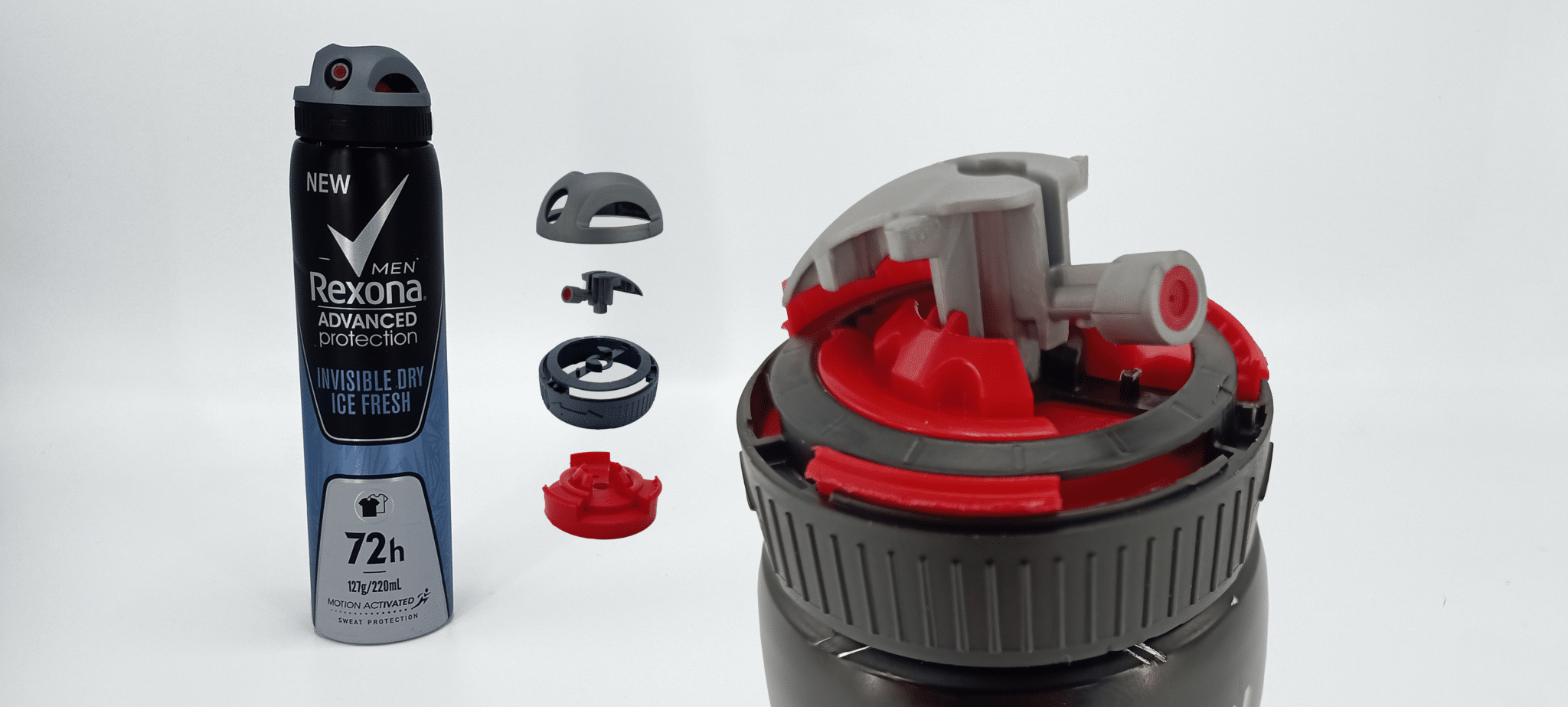

The Rexona spray can is made up of four main parts, we’ve called these the:

- Spray cap actuator,

- Spray valve,

- Locking ring, and

- Frame housing.

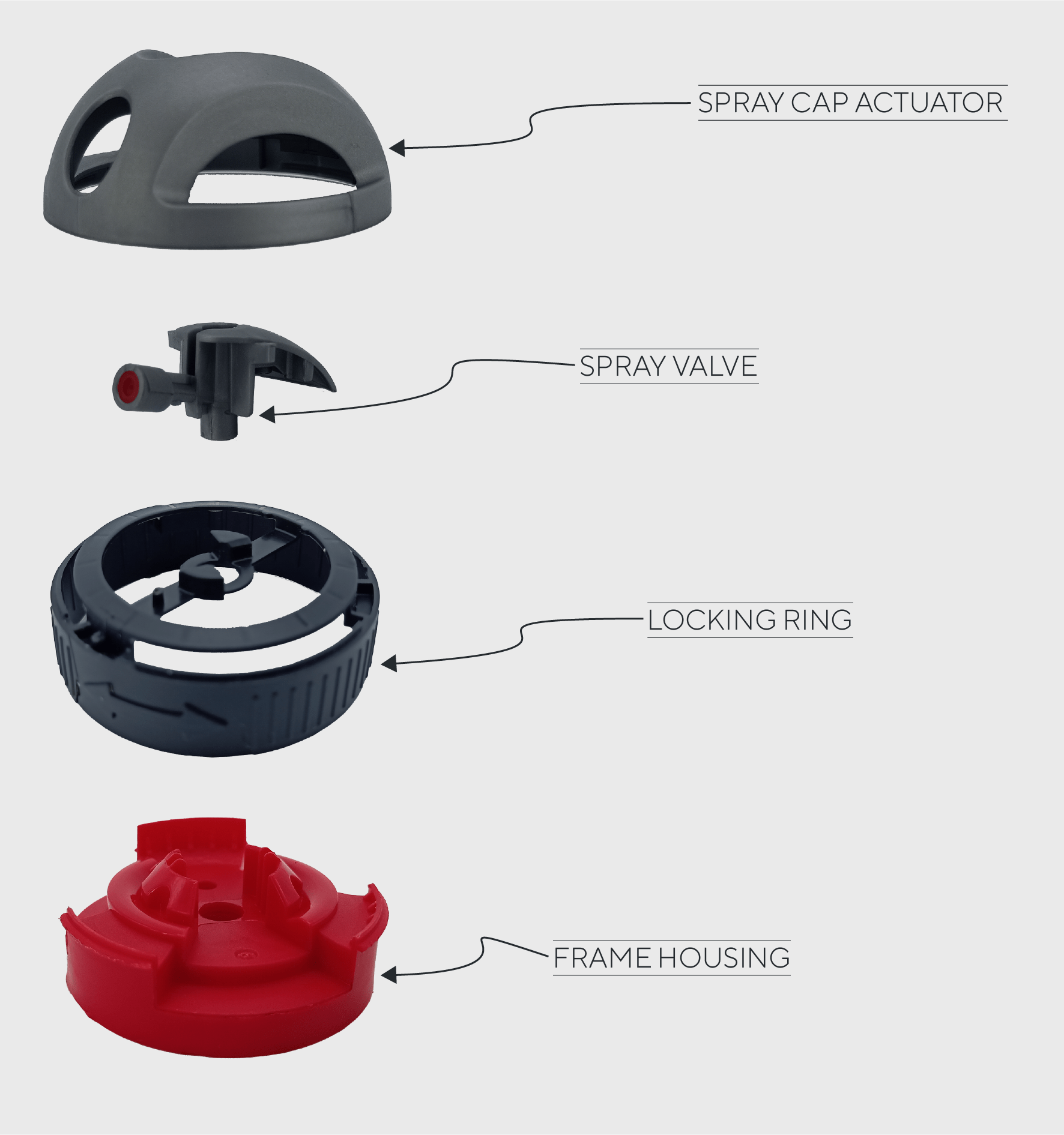

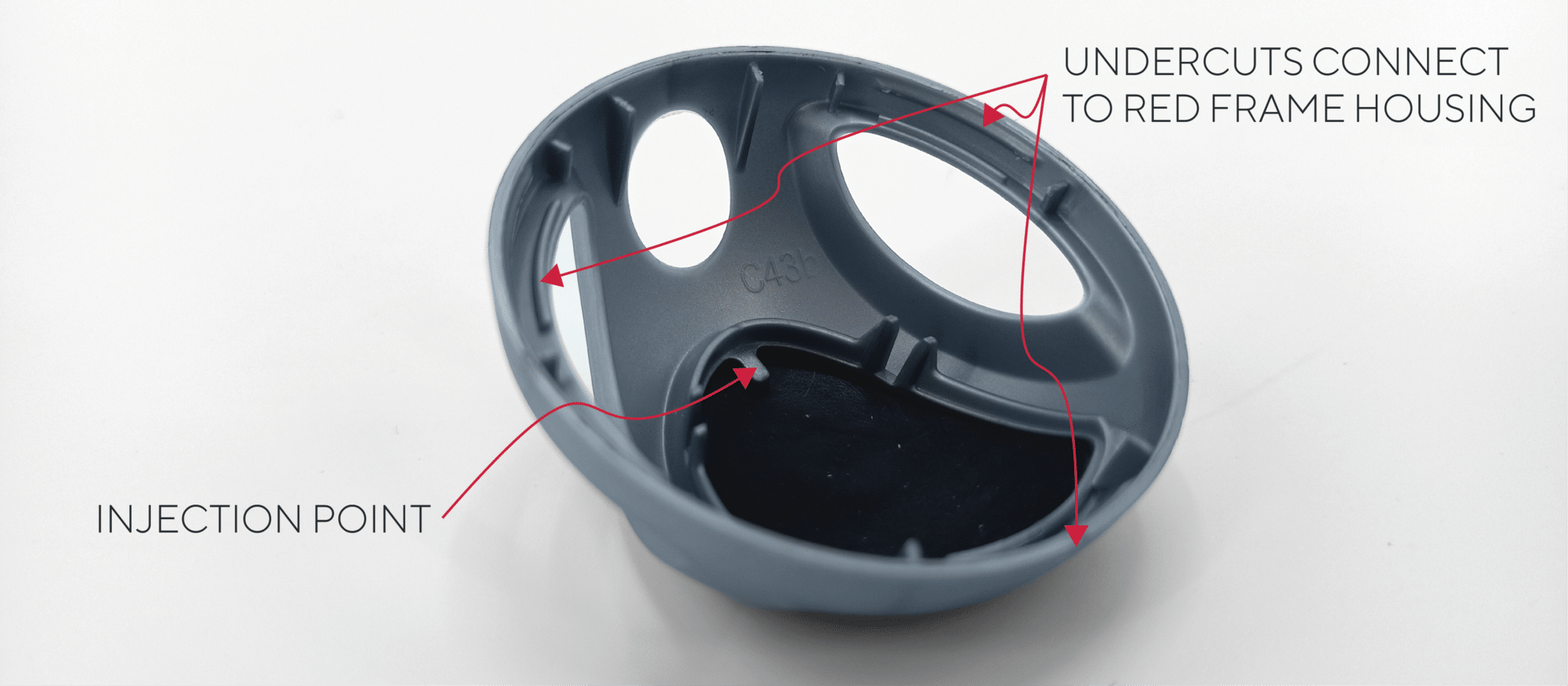

Spray Cap Actuator

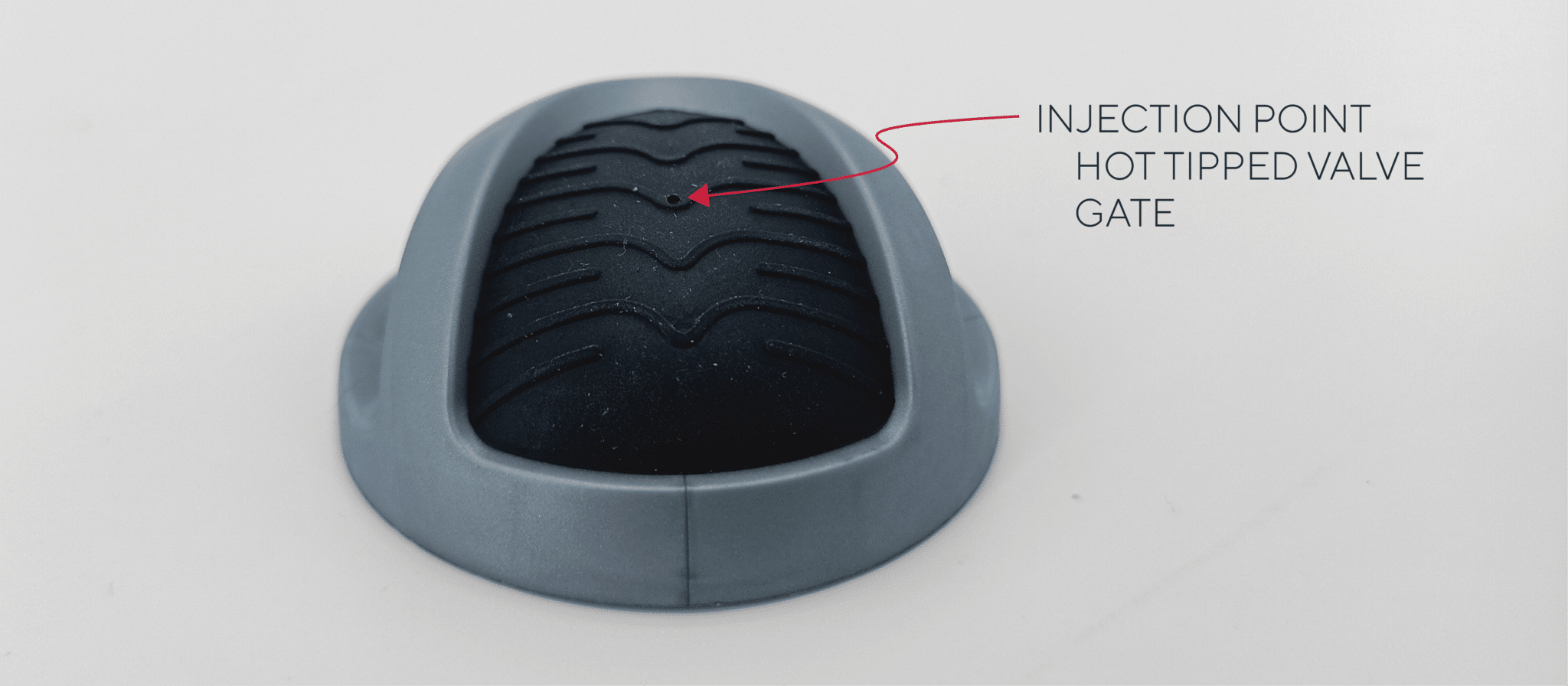

Starting with the Spray Cap Actuator, we can see the weld lines where the melt flow connects on the sides.

We can use these weld lines to understand that the injection point came from the centre of the cap actuator, most likely on little extension of material that is on the underside of the grip, although this is only assumed.

The lid also has small undercuts on the inside that allow it to grip to the red frame housing component. Due to the undercuts being so small, and the part being so pliable, the part can still be ejected from the tool despite these undercuts by most probably a stripper plate.

On the TPE/TPU grip we can see the point of injection is here. This has been done via a hot tip with a valve gate, and we know this because of the small hole in the injection point. This hole has been created by a pin that shuts off the hot tip. We can also see the flow marks on the underside of the grip, and these also indicate that this is the injection point.

Spray Valve

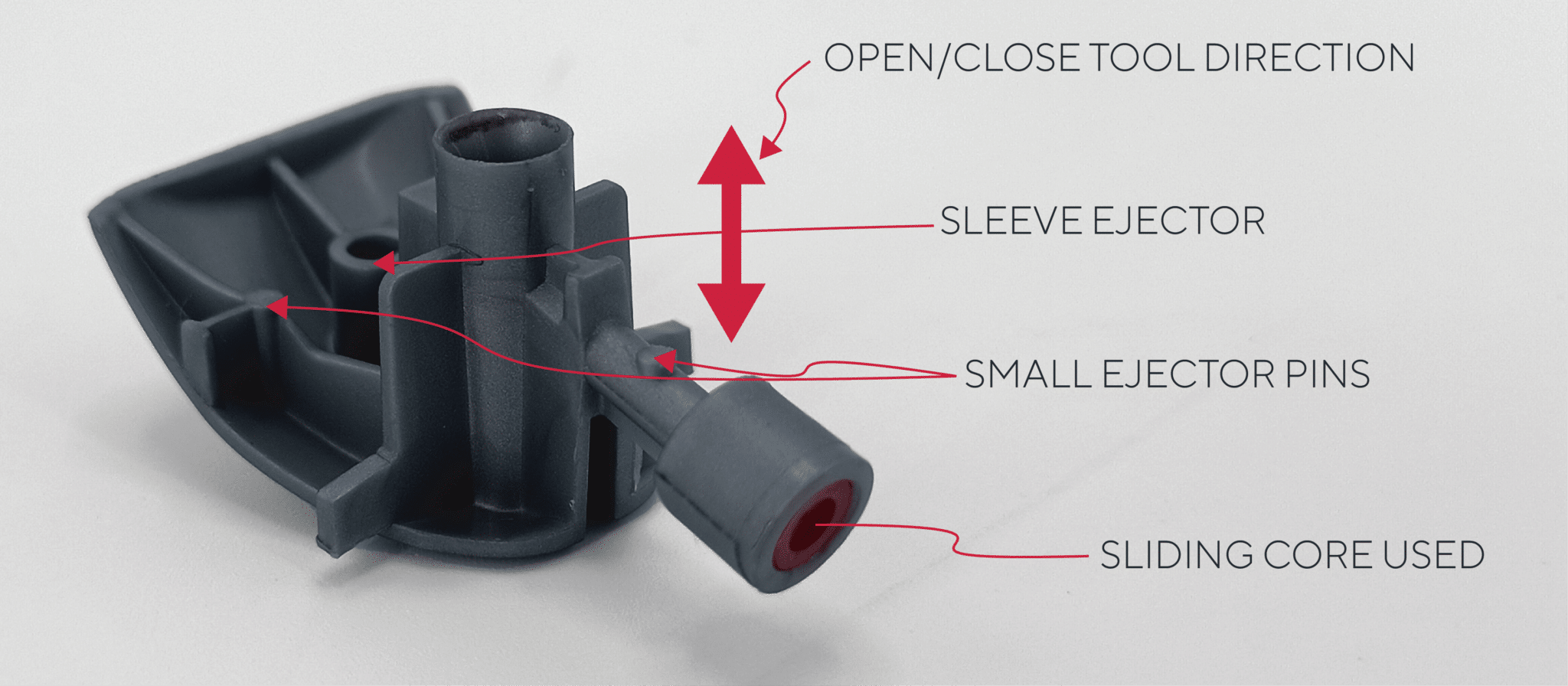

The Spray Valve is an open & close tool design with sliding cores to create the hole needed for the valve. We can see a sleeve ejector mark on the smaller hole. This sleeve ejector would be contributing the majority of the ejecting force. There are also ejectors pushing on these smaller circular wall sections. These ejectors are most likely there to keep the part from racking to one side or the other when the part being ejected. We can also see that the tool has a valve gate, from the small hole in the injection point. The spray valve is held in place by the Spray Cap Actuator when assembled.

Locking Ring

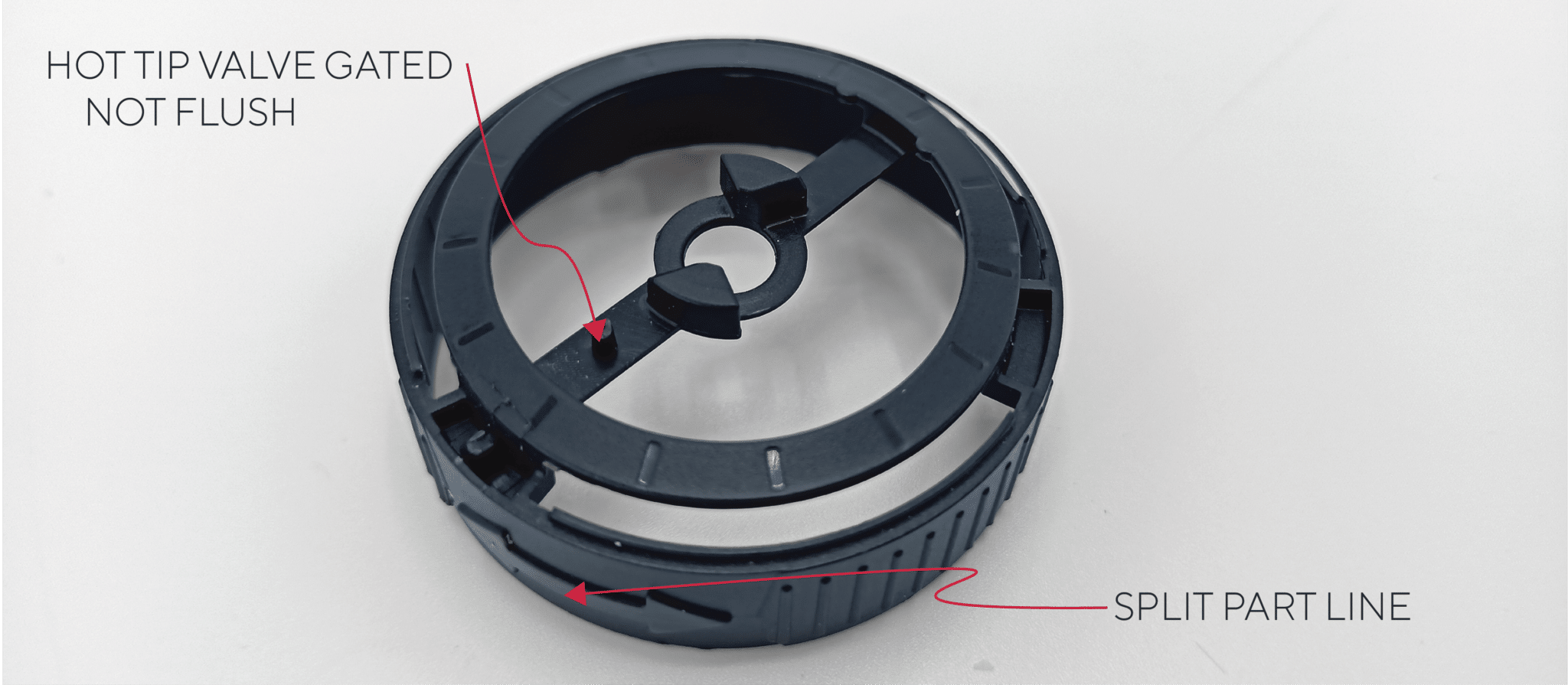

The Locking Ring, this part also has a valve gate, but instead of being flush with the part it has a small bit of extruded material on the center bridge. This is most likely done because the hot tip couldn’t get between the two cavity sections of the mould, and therefor needed to inject from a higher point. There is a split part line on the arrow sections of this tooling, showing a drop shut off to allow the arrows to be moulded without sliding cores. This part is most likely ejected with a striper plate.

There are two small male tabs on the inner of the outer ring that are barely noticeable, but these mate with the female notches on the red Frame Housing to create the open and closed positive stops. There is also an extruded cam in the center ring, connected via a section running across the diameter of the component. This mates with center ribs on the red Frame Housing to create a stop for opening and closing that stops the lock from turning any further than it should.

Frame Housing

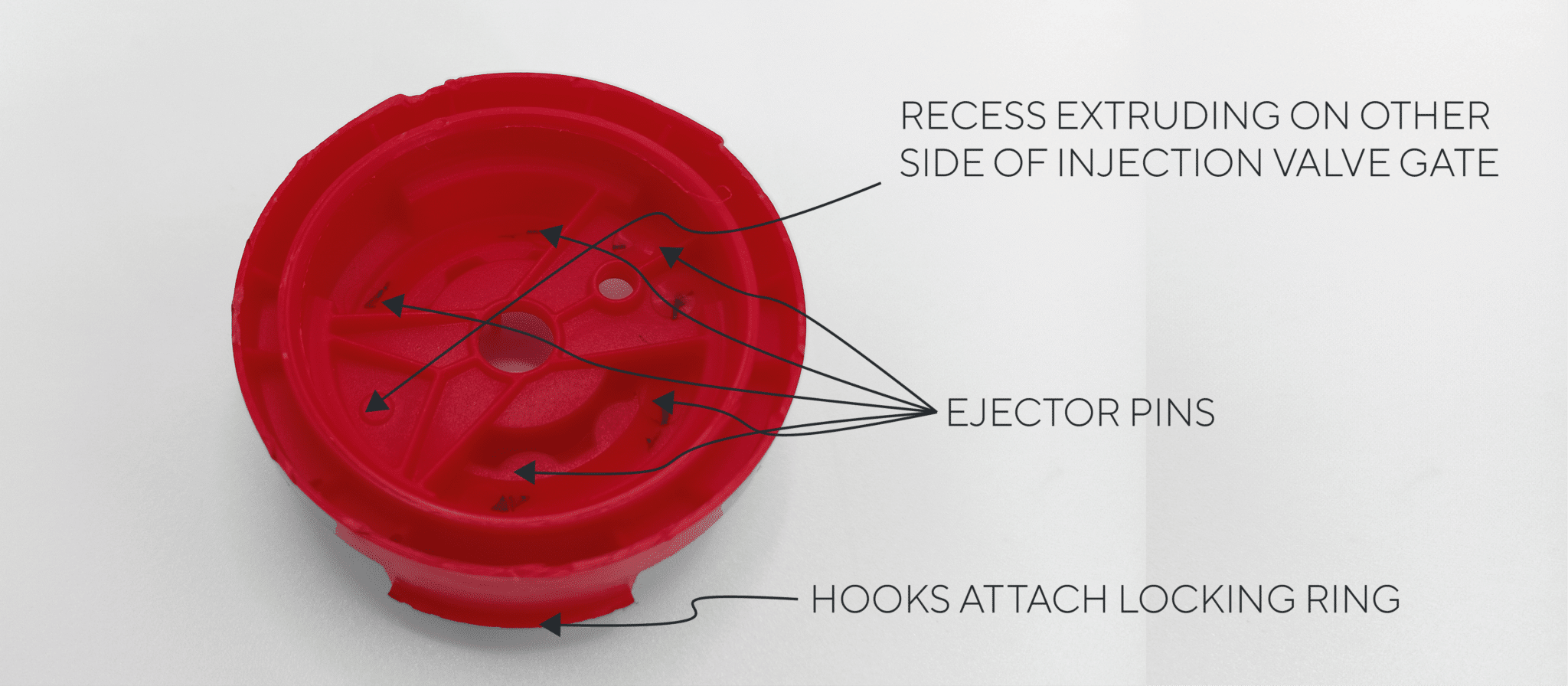

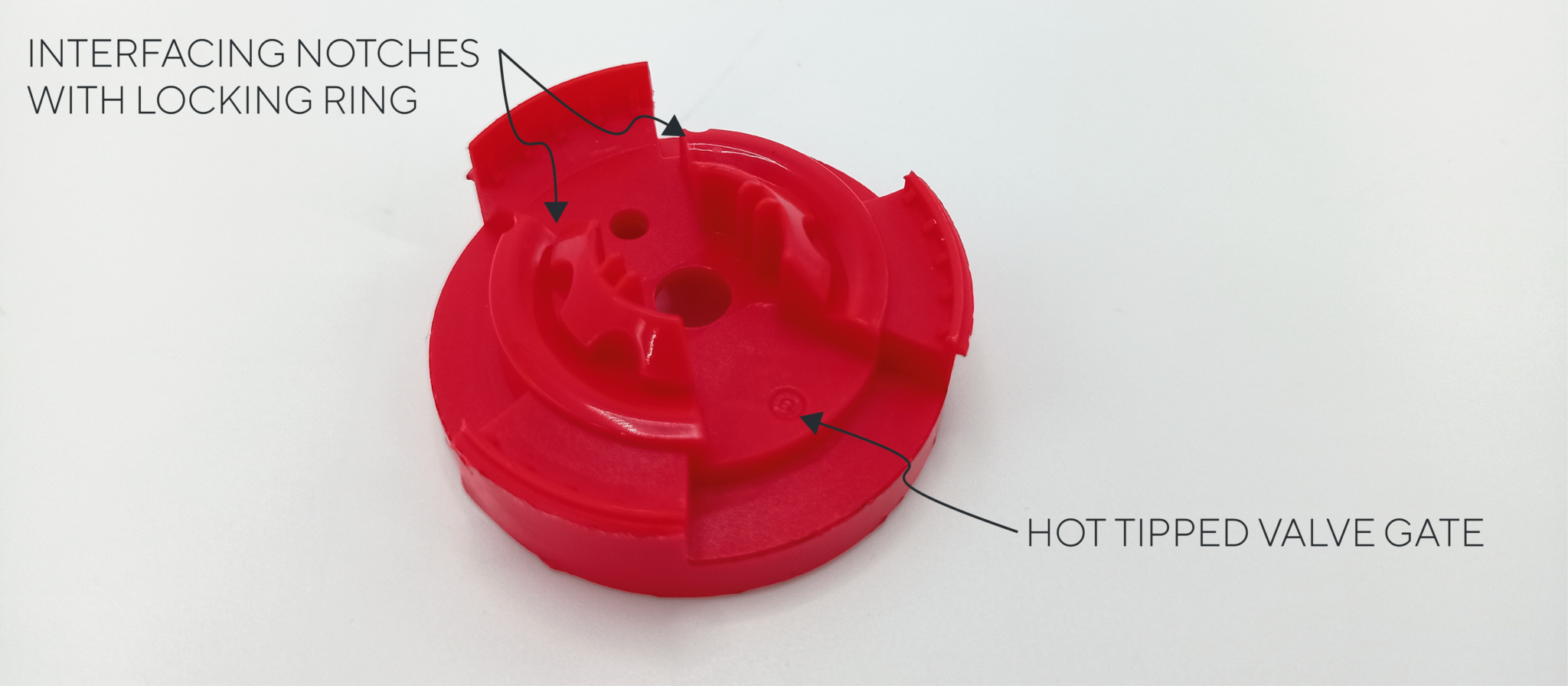

This bottom part is the Red Frame Housing. This part has hooks in 3 places along the outside that allow the Locking Ring to distort and attach with ease but stop it from being detached without excessive force. It is ejected via ejector pins, and these pins can be seen in these spots due to these small identifying marks.

This part also has a valve gate, but instead of being flush with the part surface it is recessed into the part. This is done to eliminate any chance of a gate leaving any uneven material or residue that could affect the Locking Ring as it rotates on top of it. There are two small female notches on the inner ring that are barely noticeable, but these mate with the two small male tabs of the Locking Ring to create a positive catch “feel” when open and closed. There are also ribs in the center of the part that the cam on the Locking Ring mates with. This cam hit’s the ribs and creates positive stops between both parts when fully opened or full closed controlling it from going any further than it should.

So How Does It Square Up?

The plastic components that make up the Rexona Spray Can are incredibly well designed and thought out. You can tell that the people who designed this product knew what they were doing. The parts look good, works effectively, and uses minimal material. By minimising material, the product can be manufactured quicker, and for less costs.

Perhaps the only downside of these components or this product, is that it is clear their tooling would have been incredibly expensive. Hot tipped valve gates don’t come cheap – and chances are these products are moulded from very large tools with many cavities.

What product should we look at next? Send us through your suggestions! P.S. All I could smell in the office was Rexona deodorant during the making of this product deconstruction & review….

At Dienamics, we offer a range of comprehensive services in every step of the product manufacturing process. These include:

- Product design, including concept assessment and project scoping

- Prototyping and process and materials testing

- Manufacturing, injection moulding, production, assembly, and packaging

Contact us today if you have a product you’re looking to get designed & manufacture!

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox