Look around you, how many electronic devices can you see? …3….4….8? More than 23.5% of household fires are started by electrical products or electrical appliances; such as televisions, radios and power adapters. Often, these products are made from plastic or contain plastic components. Classed as ‘ordinary combustibles,’ most plastics are excellent fuels and are in the same category as wood.

Whilst there exists no completely fireproof plastic material, some plastics are inherently fire resistant. For others, that don’t inherently possess fire resistance, additives, made from metal hydroxides, phosphorous compounds or nitrogen compounds, etc., can be combined with the raw material to improve this quality. Using fire resistance plastic for your product will not prevent internal fires, rather it will mitigate the risk of fire spreading beyond the inside of the product. This is often required in order to meet product safety standards.

Not many raw plastics meet the requirements of V-0, 5VB, or 5VA classes. To reach these high classes most plastics do require ‘additives.’ Often this is undesirable because it adds to the material cost, can cause manufacturing issues and inconsistencies, and reduces the mechanical properties of the plastic.

Often fire rating classifications and standards are written in convoluted and overly detailed, difficult to understand, ways. In simple and as few words, fire resistance in plastics generally refers to three main criteria:

- Does the material self-extinguish if the plastic is set alight and then the heat source is removed?

- If the plastic is set alight, does the fire easily propagate to surrounding materials?

- Does the material resist ignition to begin with?

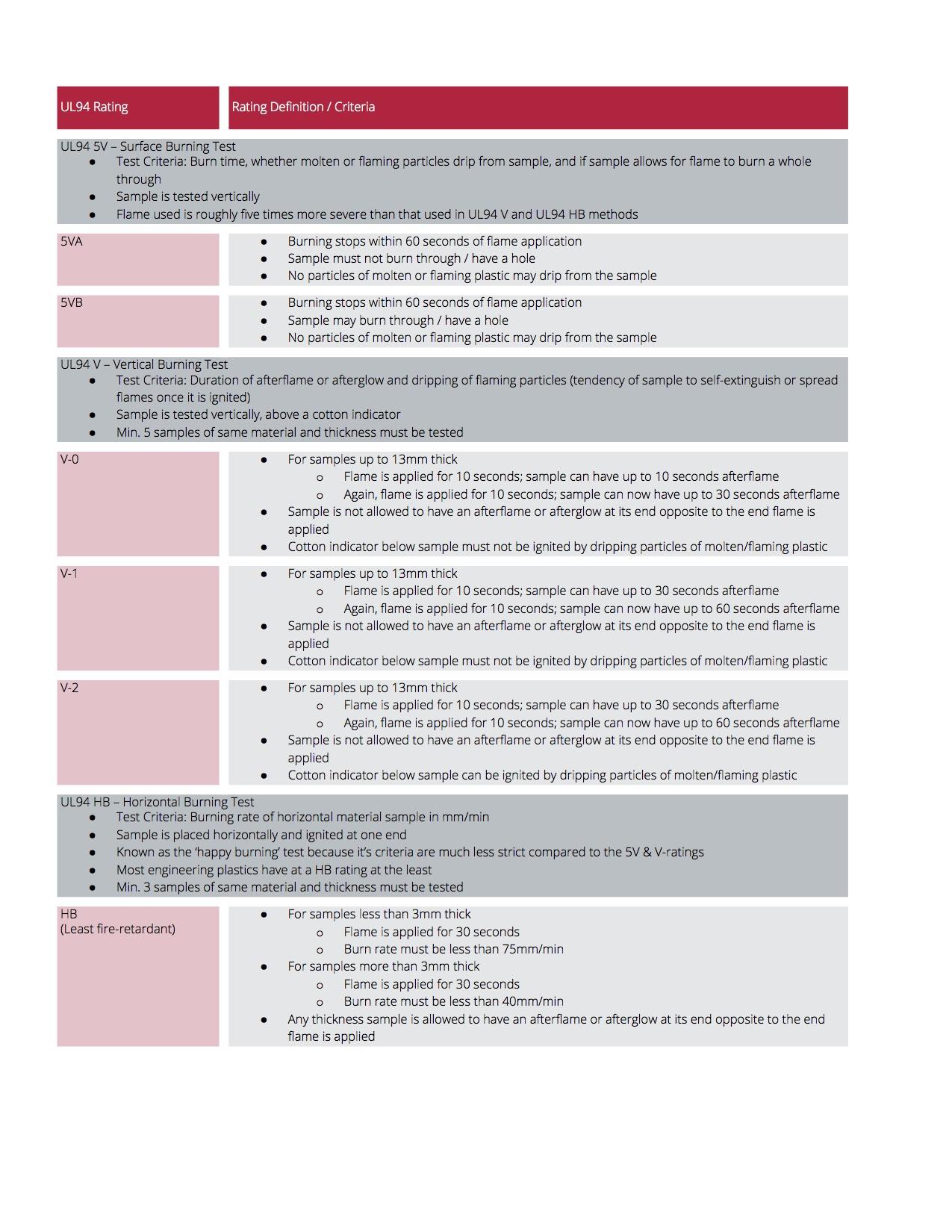

One of the most internationally recognized Flammability Testing standards, UL94, is specified by independent United States organization Underwriters Laboratories (abbreviation UL). This standard sets out methods for the testing of raw plastic material samples as well as the criteria for each of the fire ratings. Ratings are given according to sample burn times, vertical or horizontal burn distance, time for flame to extinguish and the ignition of a cotton indicator. The results of these tests vary with different sample thicknesses. The six UL94 fire-retardant ratings are listed below in Table 1. from most fire-retardant to least fire-retardant.

Table 1. UL94 Rating Definitions / Sourced here.

Not many raw plastics meet the requirements of V-0, 5VB, or 5VA classes. To reach these high classes most plastics do require ‘additives.’ Often this is undesirable because it adds to the material cost, can cause manufacturing issues and inconsistencies, and reduces the mechanical properties of the plastic.

When looking at different plastic materials, it is very important to keep in mind exactly what properties your product requires; in most cases a conservative approach often works out the best, without undue expense.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox