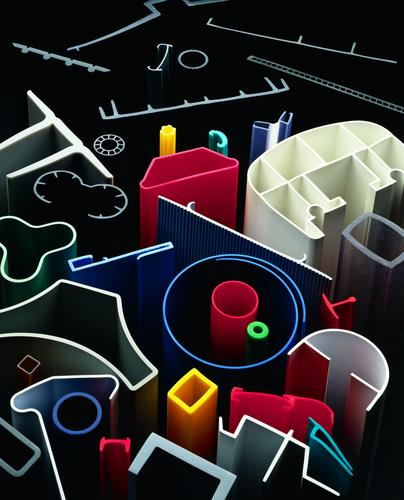

Extrusion is a simple process and is used the world over, from making spaghetti to window frames and door seals. Plastic Extrusion is when a material is being forced through a die (think a plate with a profile cut into it) and the plastic takes the form of that profile. In plastics, extrusion creates long strips with the same profile continuously. Plastic extrusion can make products with a range of material types.

Most Plastic extruders can produce profiles that have an average maximum size of 250mm cross section, and the length is determined by the length of the factory. The extrusion process can be hot and cold extruded, however both processes can be energy intensive. Examples of plastic extruded products are pipes, seals, and tubes.

The benefits of Plastic extrusion include a low capital cost in tooling, in comparison to Injection Moulding tools and a relatively high speed of production with approximately up to 20 metres of product per hour. If you’d like to talk about creating or tooling your extruded product feel free to contact us.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox