$12 Outdoor Plastic Chair off Gumtree Not as Mechanically Sound as First Thought

Local father figure, and little league coach, Bryan Walters (42) returned home yesterday after a day in the sun to sit down and enjoy a cold-one on his newly renovated outdoor patio. Much to Mr. Walters’ dismay, the bargain lawn chair he bought the week previous for $12 off of Gumtree snapped like an 80yr-olds arthritic hip.

“I knew I’d put on a few kilos since Christmas,” said Walters, “but I wouldn’t have thought I was that bad.”

Luckily, he was able to minimise spillage and later sipped his beer standing.

Plastics & UV Radiation

Alike the skin on Bryan’s balding head, plastics are affected by UV rays. A number of variables determine what UV exposure does to plastic products and there is a number of ways to mitigate its affects; it’s just about knowing where to start and figuring out what the best option is for your specific product or environment of use.

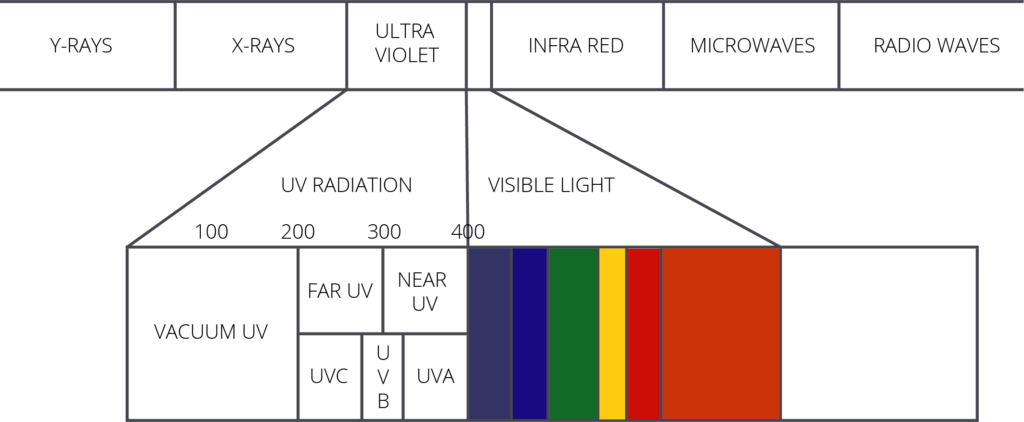

UV (ultraviolet) radiation is on the electromagnetic spectrum, having a higher energy level than visible light yet less than X-Ray radiation (Figure 1). There are three types of UV:

• UVA – skin tanning type

• UVB – burns skin, makes you go red

• UVC – which doesn’t affect our skin Like A and B UV and is rather a type of germicidal light radiation that inactivates bacteria and viruses; UVC lights are used in hospitals to sterilise equipment such as scalpels

Figure 1: Electromagnetic Spectrum – UV Radiation

All three types of UV have photochemical effects on plastic polymers. In some cases UV can actually positively benefit it, though more often than not UV causes plastics to change colour, become brittle, and develop a chalky appearance (think stadium seats, plastic watering cans, or the plastic trimming on your car).

Protecting Against UV

Had Bryan used his vinyl revival spray he uses on his car dashboard on his chair he may have found himself sitting comfortably, enjoying the afternoon sun. These sprays are polyurethane-acrylates and can provide a short term solution to protecting your plastic products. Though the ideal solution is to add additives when injection moulding the plastic product. These additives come in the form of stabilisers – that slow the effects of UV light, absorber – that absorb the UV so that the plastic itself does not, and blockers – that reflect UV.

At Dienamics our design team can determine the best additives for your product to ensure its’ longevity and performance whilst also meeting your sustainability goals. A sustainable product is one that functions correctly within its’ usable lifetime.

Book a session with us to come in and discuss the best way for you to manufacture your idea. Don’t be like Bryan.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox