Selecting the right plastics manufacturing method for your project requires navigating a varied landscape of options, each with its unique benefits and challenges. This can be a daunting task. This guide aims to simplify that choice by providing a detailed comparison of popular plastics manufacturing techniques. From injection moulding and blow moulding to advanced 3D printing methods, we’ll explore what each process offers. This information is crucial for anyone looking to make informed decisions at any stage of product development, ensuring your design not only takes shape but does so in the most efficient and effective way possible.

Injection Moulding

Injection moulding involves melting plastic pellets and injecting the molten plastic into a mould under high pressure. It’s ideal for mass-producing high-precision, high-quality parts with a consistent finish, valued for its efficiency and precision. While it offers high-volume production with consistent quality, the upfront costs for mould design and manufacturing can be significant, making it less suitable for small runs.

Pros:

- High Efficiency: Once the mould is created, production is fast and cost-effective, especially for large volumes.

- Precision: Capable of producing complex shapes with tight tolerances.

- Material and Colour Flexibility: Supports a wide range of materials and colours.

Cons:

- Upfront Costs: High initial investment for mould design and production.

- Design Restrictions: Not all part designs are suitable for injection moulding due to limitations in mould design, however with considered, innovative design and good material choices a wide variety of complexities are possible. When it comes to mass-manufacturing complex parts, injection moulding is the go.

Blow Moulding

Blow moulding shines in creating hollow plastic parts, such as bottles and containers. The process involves extruding a heated plastic tube, which is then inflated inside a mould. Its main advantage is the ability to produce uniform, thin-walled items economically, though the method is limited in the complexity of shapes it can produce.

Pros:

- Ideal for Hollow Parts: Perfect for creating bottles, containers, and other hollow shapes.

- Cost-Effective for High Volume: Economical for large production runs after initial setup costs.

Cons:

- Limited to Hollow Parts: Not suitable for solid objects.

- Initial Costs: Like injection moulding, the mould costs can be high.

Image courtesy of APR Tanks

Rotational Moulding

In rotational moulding, plastic powder is placed inside a mould, which is then heated and rotated along two perpendicular axes. This coats the interior of the mould evenly, forming hollow parts. This method is perfect for large, hollow parts with uniform wall thickness, such as tanks. Rotational moulding allows for intricate shapes and sizes but has longer cycle times and is generally more costly per unit than other moulding processes.

Pros:

- Uniform Wall Thickness: Excellent for parts that require uniform wall thickness without internal stresses.

- Design Flexibility: Allows for complex shapes and sizes, including double-walled and internally ribbed structures.

Cons:

- Slower Production: Cycle times are longer compared to other methods.

- Material Limitations: Not all plastics are suitable for rotational moulding.

Thermoforming

Thermoforming involves heating a plastic sheet until pliable, then forming it over a mould using vacuum, pressure, or mechanical means. Thermoforming is widely used for packaging and non-critical parts. It’s quick and cost-effective for prototypes and has a short lead time. However, it struggles with consistency in wall thickness and is limited in the detail it can achieve. Sometimes thermoforming is used in conjunction with injection moulding, in a process call in-mould decorating. Keep your eyes out for a future blog on this topic.

Pros:

- Low-Cost Tooling: Moulds can be made from less expensive materials, reducing upfront costs.

- Rapid Prototyping: Quick and cost-effective for prototypes or small production runs.

- Material Efficiency: Excess material can be trimmed and recycled.

Cons:

- Thickness Variation: Wall thickness can be inconsistent, depending on the draw depth.

- Detail and Depth Limitations: Less capable of forming very deep or highly detailed parts.

- Material Waste: Excess material from the forming process may lead to higher waste.

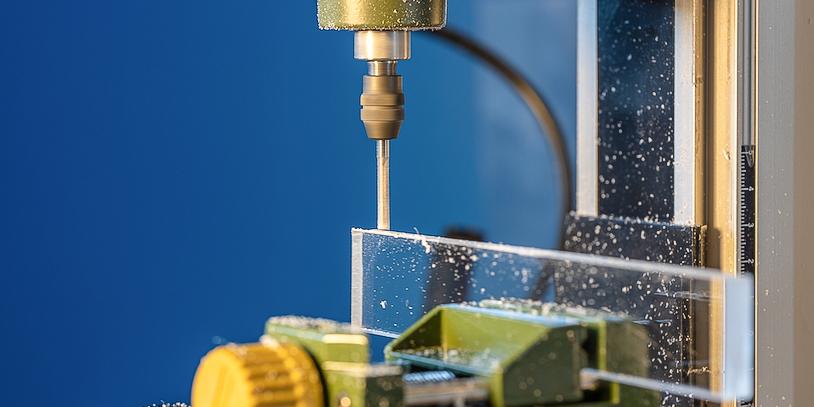

Plastics Machining and Fabrication

Plastics machining and fabrication encompass a variety of processes used to shape, form, and assemble plastic parts. These methods, including CNC machining, drilling, turning, and milling, are subtractive processes that remove material from a plastic block or sheet to achieve the desired shape. Fabrication techniques may also involve welding, bonding, and assembling multiple pieces to create complex structures. Machining and fabrication offer custom shapes and sizes and a high degree of flexibility and precision but can lead to higher material waste and costs for large-scale production.

Pros:

- Precision and Flexibility: CNC machining offers high precision and the ability to produce complex shapes and fine details.

- No Moulds Required: Unlike injection moulding, machining does not require expensive moulds, making it cost-effective for prototypes and small to medium production runs.

- Wide Material Selection: Machining and fabrication can be performed on a vast array of plastics, allowing for a broad selection of material properties and applications.

- Quick Turnaround: Without the need for mould creation, the turnaround time from design to finished part can be relatively short.

Cons:

- Material Waste: Being subtractive processes, machining and fabrication can produce significant material waste compared to moulding techniques.

- Cost Per Part: For high-volume production, the cost per part can be higher than moulding methods due to the time-consuming nature of the machining process.

- Limitations on Part Size: The size of parts can be limited by the size of the machining equipment and the availability of suitable plastic blocks or sheets.

Vacuum Casting

Vacuum casting, also known as urethane casting or polyurethane casting, is a method used to create small to medium volumes of high-quality, precise replicas of a master model. The process involves creating a silicone mould around a master model (which can be produced via CNC machining, 3D printing, or another method) and then using a vacuum to draw liquid polyurethane resin into the mould. The vacuum helps to ensure that the resin fills the entire mould evenly and without air bubbles, resulting in highly accurate and detailed parts. It is particularly useful for validating designs, conducting market tests, or fulfilling requirements for small batches of end-use parts where the cost and time investment of traditional moulding methods are prohibitive.

Pros:

- High-Quality Replicas: Vacuum casting produces parts with excellent surface detail and fidelity to the original model.

- Fast Turnaround: The process is quicker than creating new moulds for injection moulding, making it ideal for short production runs and rapid prototyping.

- Versatility in Materials: A range of polyurethane resins are available, mimicking various plastics’ properties, including rigidity, flexibility, heat resistance, and more.

- Cost-Effective for Small Batches: It is a cost-effective solution for producing a small number of parts, as the silicone moulds are less expensive and faster to produce than metal moulds.

Cons:

- Limited Mould Life: Silicone moulds degrade over time and with use, typically yielding 20 to 25 casts before losing accuracy and detail.

- Not Suitable for Large Volume Production: Due to the limited life of silicone moulds and the labour-intensive casting process, vacuum casting is not cost-effective for large-scale production.

- Material Properties: While a wide range of resins are available, the mechanical properties of vacuum-casted parts may not match those produced by methods like injection moulding, particularly for long-term use or under stress.

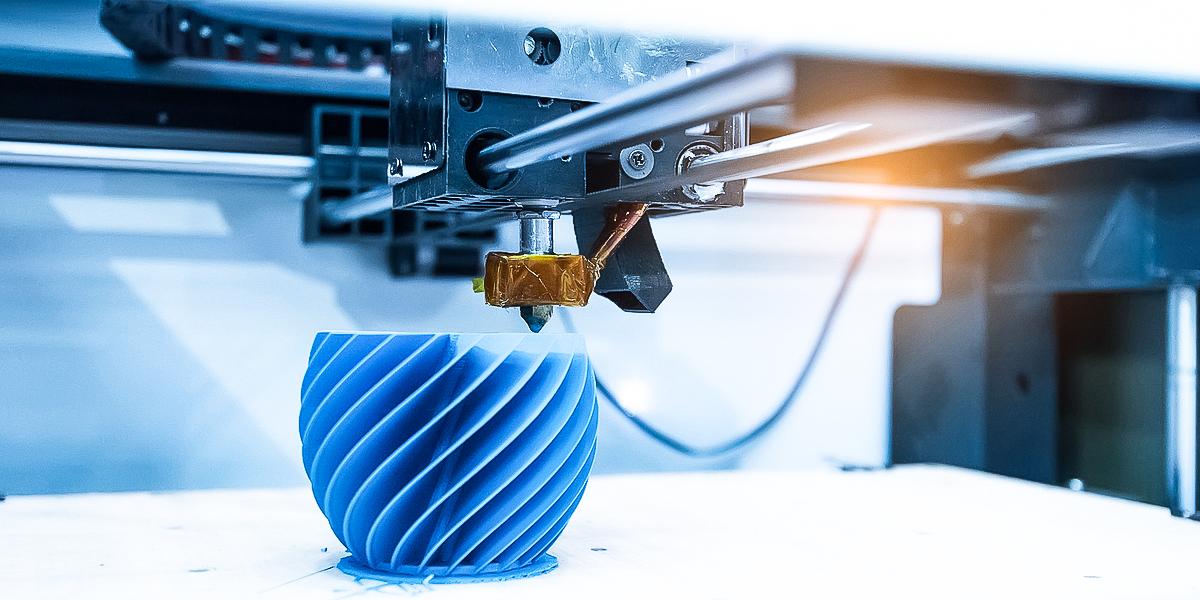

FDM Printing (Fused Deposition Modelling)

FDM printing creates objects by extruding melted plastic filament in a layer-by-layer fashion. This subset of 3D printing is popular for prototyping and functional parts due to its versatility and ease of use. While it allows for complex designs and rapid iteration, the surface finish can be rough, and the material strength may not match that of parts made through traditional manufacturing.

Pros:

- Design Flexibility: Can produce complex geometries that are difficult or impossible with traditional methods.

- Rapid Prototyping: Allows for quick iteration of design ideas.

Cons:

- Surface Finish: Parts may require post-processing to achieve a smooth surface.

- Material Strength: Parts are generally less strong than those made with traditional manufacturing methods.

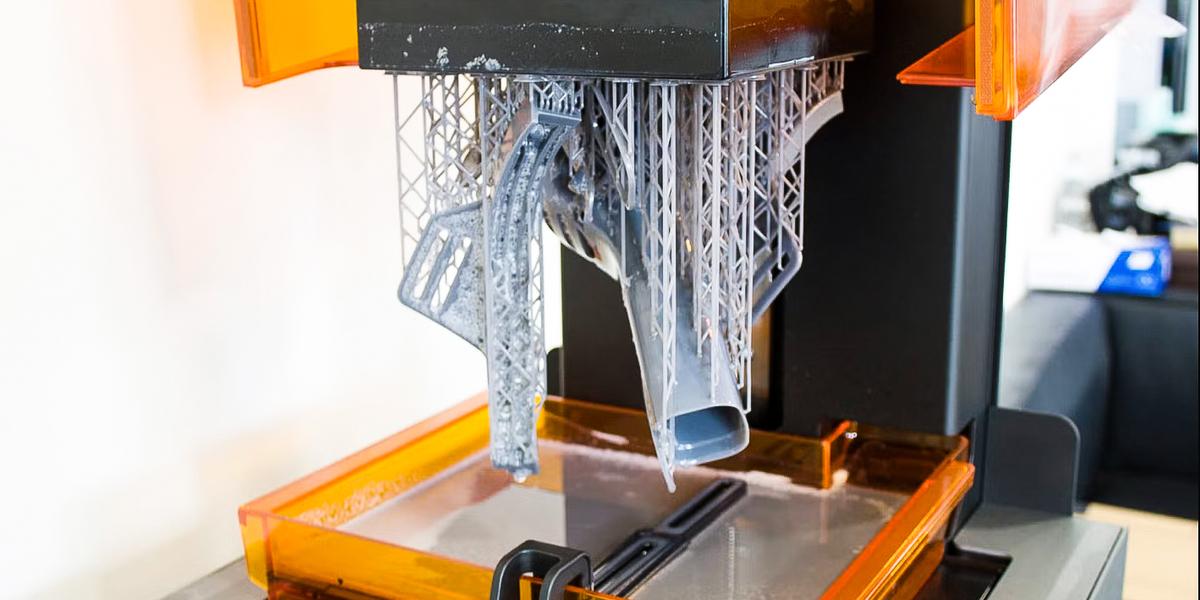

SLA Printing (Stereolithography)

SLA printing (Stereolithography) uses a laser to cure liquid resin into solid plastic in a layer-by-layer approach. This process is preferred for detailed prototypes and models requiring a smooth finish, but the range of materials is limited, and the process can be slower and more costly than other 3D printing methods. DLP

Pros:

- High Detail and Finish: Capable of producing parts with fine details and a smooth surface right out of the machine.

- Precision: Ideal for applications requiring tight tolerances.

Cons:

- Material Limitations: Limited to photopolymer resin materials, which may not have the same properties as other plastics.

- Cost and Speed: Generally, more expensive, and slower than FDM printing for producing parts, making it less suitable for high-volume production.

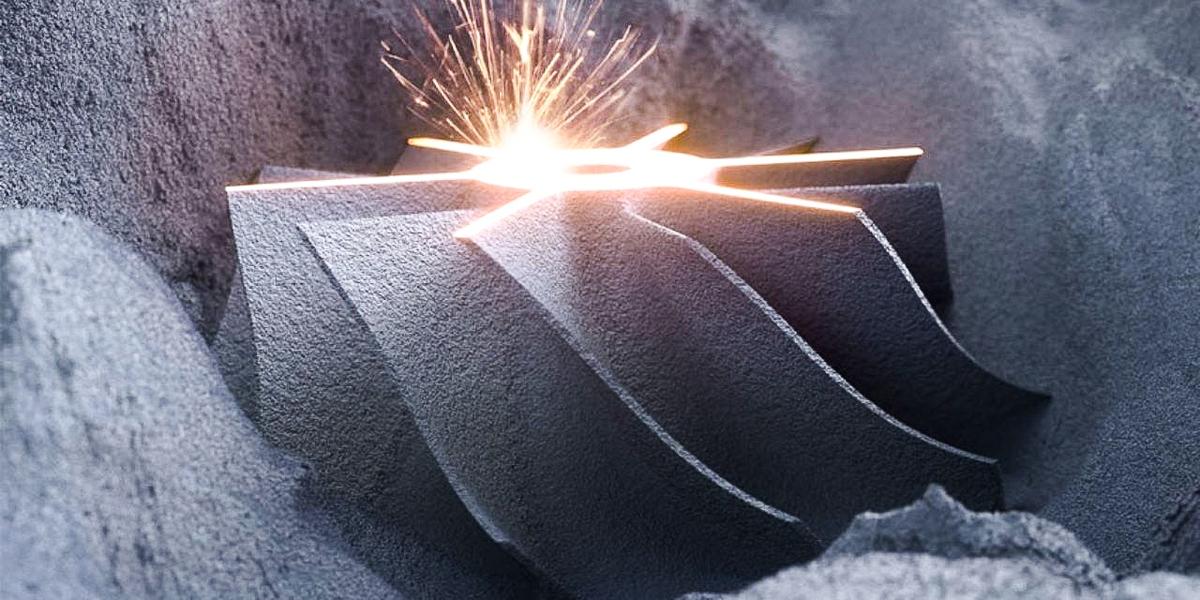

SLS Printing (Selective Laser Sintering)

SLS printing uses a laser to sinter powdered material, binding it together to form a solid structure. SLS is ideal for functional prototypes and small-batch production, offering strong parts with complex geometries. Though it provides great design freedom and material options, the surface finish can be grainy, and the process requires significant post-processing.

Pros:

- Strong, Functional Parts: SLS parts are durable and can be used for functional applications.

- Design Freedom: Like SLA, it allows for the creation of complex designs, including moving parts and interlocking pieces without assembly.

- Material Options: Offers a range of materials, including nylon and other engineering plastics, providing various mechanical properties.

Cons:

- Surface Finish: While stronger, the surface finish of SLS parts can be rough and may require post-processing.

- Cost and Production Time: The cost of SLS printing and the time it takes to produce parts can be higher compared to other 3D printing methods, though generally lower than SLA for comparable parts.

Making the Decision

When choosing the right plastics manufacturing method for your project, consider the following factors:

- Volume: How many parts do you need? High-volume projects may benefit more from methods like injection moulding, whereas low-volume or prototype projects might be better suited to 3D printing or thermoforming.

- Complexity: What level of detail and complexity does your part require? 3D printing technologies like SLA and SLS are excellent for complex geometries that are challenging or impossible with traditional manufacturing.

- Customisation: Do each of your products require full customisation, or partial customisation? 3D printing enables the creation of custom parts through insert overmoulding, where a 3D-printed part is inserted into a mould and then encased in injected plastic, resulting in a cost-effective, customizable moulded part.

- Material Properties: Different manufacturing methods offer access to various materials. Consider the mechanical, thermal, and chemical properties you need for your application. Traditional plastics manufacturing methods such as moulding and machining have access to a wide range of materials compared to 3D printing which is limited.

- Cost: Initial setup costs (e.g., moulds for injection moulding) can be high, but per-part costs decrease significantly at scale. Conversely, 3D printing has lower setup costs but might not scale as cost-effectively.

- Finish and Aesthetics: Consider the desired appearance and finish of your final product. Some methods, like SLA printing, provide a high-quality finish off the machine, while others may require additional post-processing.

- Precision: How precise do you need your part to be? For many applications, vacuum forming, rotomoulding, or FDM printing are not precise enough. Here, injection moulding, SLS and SLA printing shine.

Conclusion

Choosing the right plastics manufacturing method requires a nuanced understanding of each process’s strengths and limitations. By considering your project’s specific needs—whether that’s the intricacy of design, material specifications, production volume, or budget constraints—you can make an informed decision that aligns with your goals. Remember, each project is unique, and the best approach often involves consulting with experienced professionals who can offer insights tailored to your project’s requirements. With over 25 years of design, tooling, and manufacturing experience, strategic decision making in design and manufacturing is ingrained in us. Get in touch, and together we can navigate the complexities of plastics manufacturing to bring your vision to life efficiently and effectively.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox