Breathing – Most people don’t give it a second thought. But for some of us, something as simple as taking a breathe is not so straightforward.

The team at AirPhysio knew they could help.

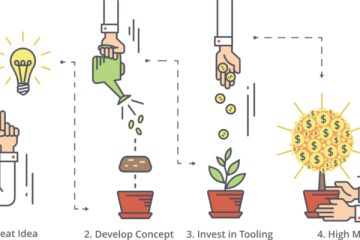

The idea

They developed the concept for the AirPhysio Oscillating Positive Expiratory Pressure (OPEP) device.

Like all good ideas, the concept is simple. Exhaling through the device trains and strengthens the lungs, while the unique oscillating action assists with the clearance of mucus.

Simple concepts are often backed by complex details. The AirPhysio team understood the functional details of their product and its target market well. The difficult part related to getting the system into production and out into the market. After trying unsuccessfully to move forward with several suppliers, AirPhysio came to Dienamics.

Design process

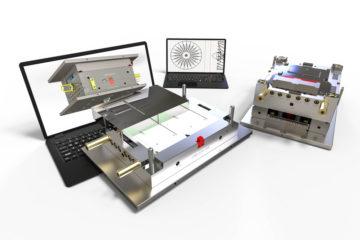

Working closely with the AirPhysio team, Dienamics created new versions of the the AirPhysio product. Given its development history, manufacturability was a strong concern, and all concepts were designed for manufacture before prototyping even started.

In that design process, Dienamics was able to eliminate several parts of the initial design, which would have added to tooling and assembly costs.

Dienamics ensured that AirPhsyio’s OPEP concept would not be compromised, and would come to market with fewer parts to manage and more cost-efficient tooling and production.

Medical devices are a demanding market, and AirPhysio had high standards. As well as ensuring functionality and unit cost parameters were kept, Dienamics also worked on the aesthetics of the product.

Tooling and manufacture

By leveraging Dienamics end-to-end control of the design, tooling and moulding process, the team was able to ensure the products looks reflected the care and attention AirPhysio had poured into its development.

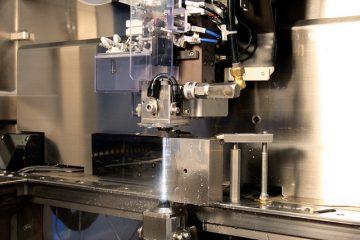

A manufacture ready design is only half the battle. Dienamics also designed and built the injection moulding tooling to suit AirPhysio production needs, and produced the product in its Brisbane facility. Dienamics has also worked with AirPhysio to help them plan to meet their expanded future production goals.

Where is it now?

Those goals look closer than ever now. After taking home several prestigious trade show prizes, the AirPhysio team is now rolling out their polished, packaged product across several countries, including exporting to China and India.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox