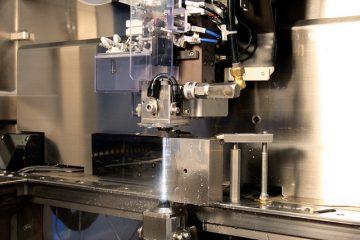

How do Surface Grinders work? A Surface Grinder grinds down metal surfaces to be perfectly flat and level. It’s an abrasive machining process, which uses a grinding wheel which is spinning at high speed to grind away differences in height. Grinding wheels are usually made of a composite material. This composite is usually some rough or course aggregate bonded together with a cementing matrix.

The two basic components of a surface grinder, is the grinding wheel and a reciprocating or rotary table. The table has a work bed which you can clamp down your work piece. If for some reason, you can’t clamp it down, you can also use an electromagnet to hold the work down tightly.

Once the work piece is set, the height is adjusted so that the workpieces is just below the grinding wheel. As the wheel comes into the desired grinding speed, the table will begin to move left and right, as it does so the work bed will raise slightly and the grinding wheel will grind of a fraction of material. The work piece is raised fractionally for the next grinding pass. The work bed will also move in and out, which allows a complete and even grinding of the workpiece.

When surface grinding, you need to understand the relationship between the grinding wheel, and the material of the workpiece. Cast Iron and most Steels, tend to grind perfectly well. However other material such as aluminum, stainless steel, brass and plastic may either become excessively hot and start to corrode or may become embedded within the grinding wheel. Both problems will slow down the process.

Grinding wheels don’t just have to be straight either. In certain circumstances, you may want to have custom grinding wheel profiles as they will impart that chosen pattern onto the surface of the ground part. Surface grinding operators have also been known to take a straight grinding wheel and machine a pattern into it.

Most surface grinders have a precision to ±0.002mm. However, as you can imagine, this is a highly time intensive process. The movement of the table can be powered hydraulically or electrically. Most surface grinders also have some hand adjust dials as well, however, it’s often the case that these are just used for the initial setup. Most modern Surface grinders are semi-autonomous and can be programmed to grind, to a certain depth, with a certain number of passes. Once the grinder is setup, it usually requires very little operator intervention.

If you’d like to learn more about surfaces grinders or if you have something that needs to be precisely ground, please don’t hesitate to contact us about a free 1-hour meeting.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox