Fundamentally, Lathes do the opposite of what most other machines do. Lathes spin the workpiece at a high speed and move a stationery cutter into the workpiece. As such it’s important to know how Lathes work.

Firstly, Lathes only have 1 axis of rotation, so if the part your working on isn’t largely symmetrical along that axis, you’re probably using the wrong machine. Usually you place your work piece into the Chuck, which is attached to the spindle. The chuck holds your work piece in place, as it spins. The chuck is usually able to grip the part from the outside diameter, or if there is a recess large enough, the chuck can also grip the piece from an inner diameter.

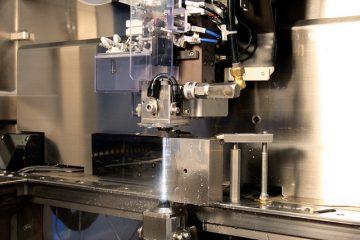

The spindle is powered by an electric motor and can usually be adjusted to various speeds. Now that the workpiece is spinning, an operator will bring their cutting tool up to and slowly cut away from the workpiece. Cutting tools, are usually flat blades, but can be other custom shapes tool. The tool is locked into toolholder, which will stop the tool from being flung out if the work piece hit the tool too hard. The tool can travel up and down the axis of rotation using a carriage that slides up and down the length of the part.

Another critical part of any lathe is the tail stock. The tailstock is similar to the spindle; however, it’s not powered, and will only turn freely if the operator attaches it to the workpiece. As such the tailstock is aligned in the center of the rotational axis. Most often, the tailstock is fitted with a drill piece, and slowly brought into the center of the work piece. This stationary drill piece cuts into the material, making a hole in the center of the part.

Lathes are critical pieces of machinery, and they are used everyday here in our workshop. While this article provided a brief overview of how lathes work, there are many more ways to turn, bore, face and cut lathe made parts.

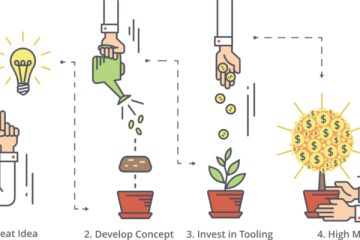

If you have a part that needs to be turned up in a lathe, or if you want some help deciding which machining process is best for your project, please contact us anytime.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox