The concept

Trevor Oxnam from Powerwin kept running into the same problem again and again. He had a solid stream of Ford vehicle owners with broken power windows coming to him for repairs. The fix was easy. It was nearly always the same weak OEM part that had broken. The problem was there was only one supplier for spares, who was the same OEM who had made this part in the first place.

Unsurprisingly the OEM was not about to lift their quality and the price for replacements was eye-watering.

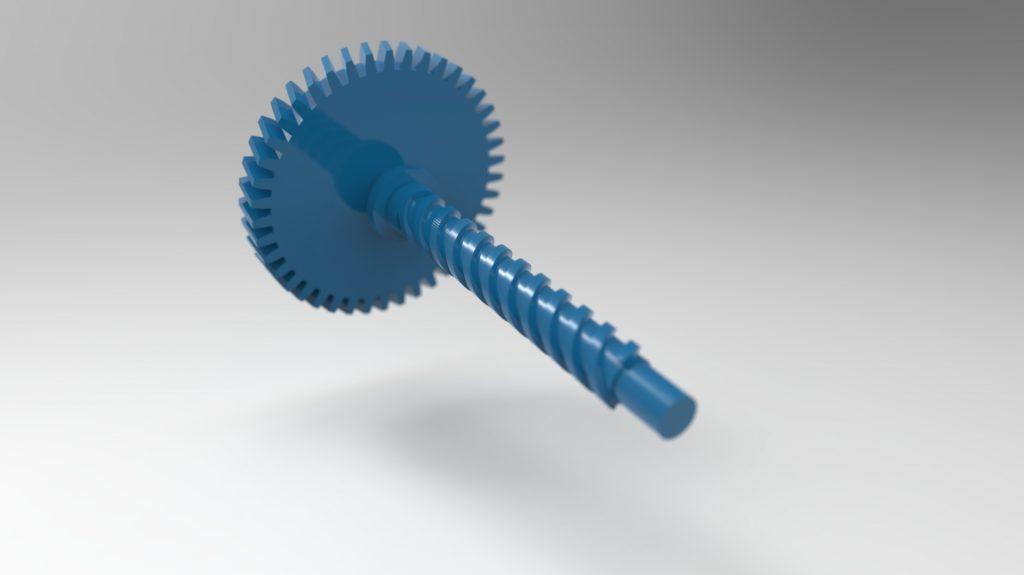

Trevor’s solution was straight forward. There was nothing special about the Worm and Wheel design of the part he needed. If the OEM wouldn’t make it properly, he would do it himself.

Problem

Trevor shopped the part around, but kept coming up blank. To be functional a worm drive must have a near flawless surface and the design of the part suggested complex tooling was needed. He kept getting turned away by tooling suppliers with the same set of excuses. The part was too difficult, the quality needed too high, the project too costly, and his required volume too low.

Finally, he came to Dienamics.

Solution

Trevor’s problem wasn’t that injection moulding the part was impossible. The real problem was the other suppliers were not willing to take a risk. Dienamics Owner Mark Serisier brought more than 30 years of real world experience to the problem and saw there were ways to make the risks acceptable. More importantly, he understood Trevor’s position in the marketplace and was able to tailor the manufacturing solution to meet Trevor’s sales plan.

Mark’s proposal to make the part met Trevor’s standards, and he gave the go ahead to move to build injection moulding tooling and put the part in production.

Mark’s tooling design did away with a lot of the expensive components the competitors had assumed were necessary. By relying on Dienamics strengths of attention to detail and excellent moulding knowledge, the tool was running smoothly within the allotted time frame.

Where is it now?

Almost 6 years on, Trevor is still selling this part on his website – fixing up broken power windows with parts better than the originals and looking at the next problem where he can beat car manufacturers at their own game.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox