Rapid prototyping is an absolute necessity in design development.

In this article, we will dive into the top reasons why you should utilise rapid prototyping for your ideas, parts, and products.

First, let’s define what rapid prototyping is. Rapid prototyping employs a diverse group of techniques to quickly and efficiently fabricate a 3D model of a physical part or assembly. This is done before undertaking manufacturing.

1. Time

Time is crucial in every project, and rapid prototyping allows you to explore and realise concepts fivefold quicker.

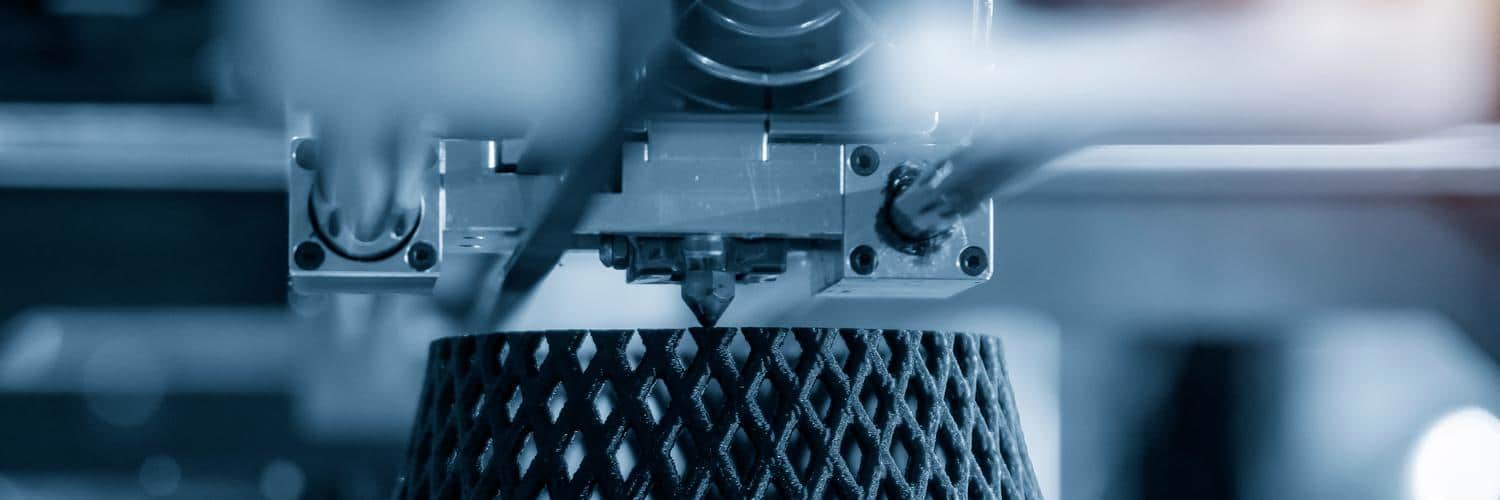

If you were to look at a drawing on a piece of paper – or even a 3D model on a computer screen, chances are that you are not getting the full story behind the picture. By having a physical model at your disposal, you will gain invaluable feedback about how your model works in its intended context. Models need to be physically handled, pushed, twisted, fitted, assembled and everything in between in order to effectively test a design.

Rapid prototyping such as selective laser sintering (SLS), fused deposition modelling (FDM), stereolithography (SLA), CNC machining, or vacuum casting all take very little time to make. Provided you or your designer have the 3D CAD (Computer-Aided Design) file ready, expect around 3–10 days for prototypes to be made – and yes, you can have multiples made at once. By finding out what changes need to be made early in the process and modifying parts based on these findings, you will save yourself a lot of heartaches, time, and money.

2. Money

Imagine this scenario – you have got a fantastic product idea, you know there is a market for it, it has been tirelessly brainstormed, researched, investigated, sketched up – you have even got it designed using CAD data. Now here is where it could all fall apart. Let’s say you skipped the prototyping phase because this product idea seems to be working on paper, right? It goes into manufacturing, which is no small feat because typically manufacturing requires a large capital investment. It is only now, in its physical form, that issues have been discovered with the product. Now the stakes are high. Tooling modification, which is costly, may not be enough to redeem the product. The entire operation could be scrapped, and tens of thousands of dollars wasted. This would have been avoided if rapid prototyping were undertaken until the product was perfectly refined.

Rapid prototyping enables the design direction to shift dramatically, encouraging trial and error with low financial risk.

3. Validation

Having a realistic physical model thanks to rapid prototyping helps in communicating the new concept to business owners, CEOs, clients, stakeholders, board members and investors. These people need to understand and approve the concept to continue funding it. By demonstrating the concepts purpose and allowing people to interact with the physical model, you can gain valuable feedback.

Physical models can also be shown to potential customers, who will give you a good idea of its desirability and help identify the actual needs of the market. You will be able to refine and validate the concept based on this pool of knowledge. There is nothing quite like the feeling of building confidence in your ideas. This validation process makes it possible to create useful and competitive products.

At Dienamics, we offer a range of rapid prototyping services. Contact us for more information.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox