Just a few decades ago, the process of developing an idea from concept to finished product took significantly longer, and was more expensive, than it is today. The advent of rapid prototyping has radically changed the product creation process for the better.

What is rapid prototyping?

A manufacturing prototype is a sample of a product. The manufacturing prototype is released to manufacturers and engineers in order to test the product’s viability before taking it to production. Factors such as durability, performance, and the cost and difficulty of production can all be gauged through the creation of an accurate prototype.

Prior to rapid prototyping technology, this process was considerably slower and more costly than it is today. Getting products out of the development stage was therefore more difficult, and many ideas died before they ever received a proper test run. Rapid prototyping technology has evolved in the past two decades to vastly improve the prototyping process.

A brief history of rapid prototyping

Dr. Herbert Voelcker, an engineering professor at the University of Rochester, began developing mathematical algorithms in the 1970s that went on to lead the creation of computer aided design (CAD) software. As computers became cheaper and more widely available, CAD helped transform the way products were designed, and changed the manufacturing process slightly.

The manufacturing process is where rapid prototyping comes in. In the late 1980s, the earliest technique, known as selective laser sintering (SLS), was introduced. The two decades that followed saw continuous improvement in both the design and manufacturing processes, making prototype development easier than ever before.

Types of rapid prototyping and their uses

While 3D inkjet printing is the newest technology and receives a lot of hype, older methods are still very commonly used. Different methods of rapid prototyping are employed, depending on the type of prototype created and the type of material worked with.

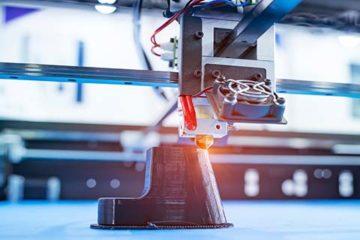

Selective laser sintering

Selective laser sintering (SLS) was developed in the late 1980s by Drs. Carl Deckard and Joe Beaman at the University of Texas. SLS uses a targeted laser to generate enough heat to bind materials together, creating a 3D model. This process works on materials such as plastic, ceramic, glass, and material.

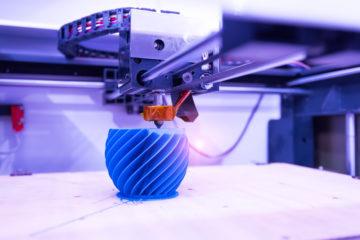

Fused deposition modelling

S. Scott Crump introduced fused deposition modelling (FDM) through his Statasys Company in 1990. The FDM method creates a 3D object using thermoplastic beads. The beads begin to harden after extrusion, creating a solid form. A major advantage of FDM is that multiple nozzles can be used to extrude beads, making possible the creation of prototypes with multiple colours and differing materials.

Stereolithography

Stereolithography (SLA) printing was introduced by Chuck Hull and 3D Systems Corp. in 1986. SLA printing is also sometimes referred to as solid imaging or optical fabrication. SLA printers create a solid object using thin layers of photopolymer resin. As each layer of resin is applied, a focused ultraviolet beam is used to cure it into a solid form.

In addition to patenting the SLA printing process, Chuck Hull also created a file format used by CAD designers to create 3D objects. This format, called STL, has become a widely adopted standard for computer-aided manufacturing and rapid prototyping.

3D inkjet printing

In 1993 the Massachusetts Institute of Technology (MIT) introduced and patented their 3D inkjet printing technology, called 3DP, for three-dimensional printing. Since then, the 3D label is used everywhere, and often you’ll hear any form of rapid prototyping referred to as 3D printing, regardless of the method used.

Z Corporation licensed 3DP technology from MIT and developed its first printer by 1996. 3D inkjet printing works by laying down rows of powdered material, and using a liquid binder to create a solid form.

How rapid prototyping improved the manufacturing process

All of the prototyping methods described above can generate an accurate model of a product, giving designers, engineers, and manufacturers the opportunity to examine many aspects of an object before undertaking full scale production. Prototypes can be evaluated for ergonomics, aesthetic appeal, and ease of manufacturing.

The SLA printing method is especially useful when testing precision parts. Using photopolymer layers as thin as 0.1 mm, SLA printers can produce parts so accurate that they can be used to test pressure, load tolerance, tension, stress tolerance, and aerodynamic performance.

Rapid prototyping has shortened the design cycle, or the amount of time it takes to go from product conception to production. A precise prototype can be created in about two days for very little money. Once a prototype is approved, factory manufacturing and tooling set up can begin, while the design phase is being completed. This allows for the reduction of manufacturing lead times, generating cost savings.

How suppliers and customers benefit

Suppliers can use models created through rapid prototyping to provide more accurate estimates about production time and costs. In addition, SLA prototypes can be used as master patterns for creating metal casts. This reduces the time needed for factory set up and tooling.

Customers benefit by being able to see and hold an accurate model of the product they want to create. They feel more confident about kicking off the production process once they’ve had the chance to evaluate a prototype and offer changes and suggestions. They also benefit greatly from cost savings in the design and manufacturing processes.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox