When you’re developing your product, the designer might come to you and say “I want to reduce the wall thickness in your part” even though you’ve said time and time again that you want a strong durable product. So why do designers push for thin walls? Let’s find out…

There are three main reasons injection moulding designers love thin walls and hate thick ones. Thin walls use less material, and so are cheaper. Thin walls cycle faster in moulding machines, which is also cheaper. Thick walls are prone to uneven cooling, resulting in parts warping. Keeping the reject rate low makes your production run, you guessed it, cheaper.

Lets dive a little deeper on each of these topics.

Thin walls naturally have a smaller volume and use considerably less material than thicker walls – so you’re already saving on part and moulding costs right there. When designing plastic parts every gram of plastic used counts. The savings might seem small at first, a gram here and a gram there, but just do some back of the napkin maths and you’ll see than of 100,000 parts, a saving of 5 grams per part will translate into over 500 kilograms of plastic.

Also, thin wall sections improve your moulding costs and turnaround times. Thin wall sections result in faster cycle times in the moulding machines as your part takes less time to cool and solidify in the mould. This allows your machine to run faster, producing more parts per hour and amortising the machine hire cost over fewer hours. Thin wall sections also help with variable shrinkage rates, because you get greater shrinkage in thicker parts. Having thin walls sounds like a good idea now right?

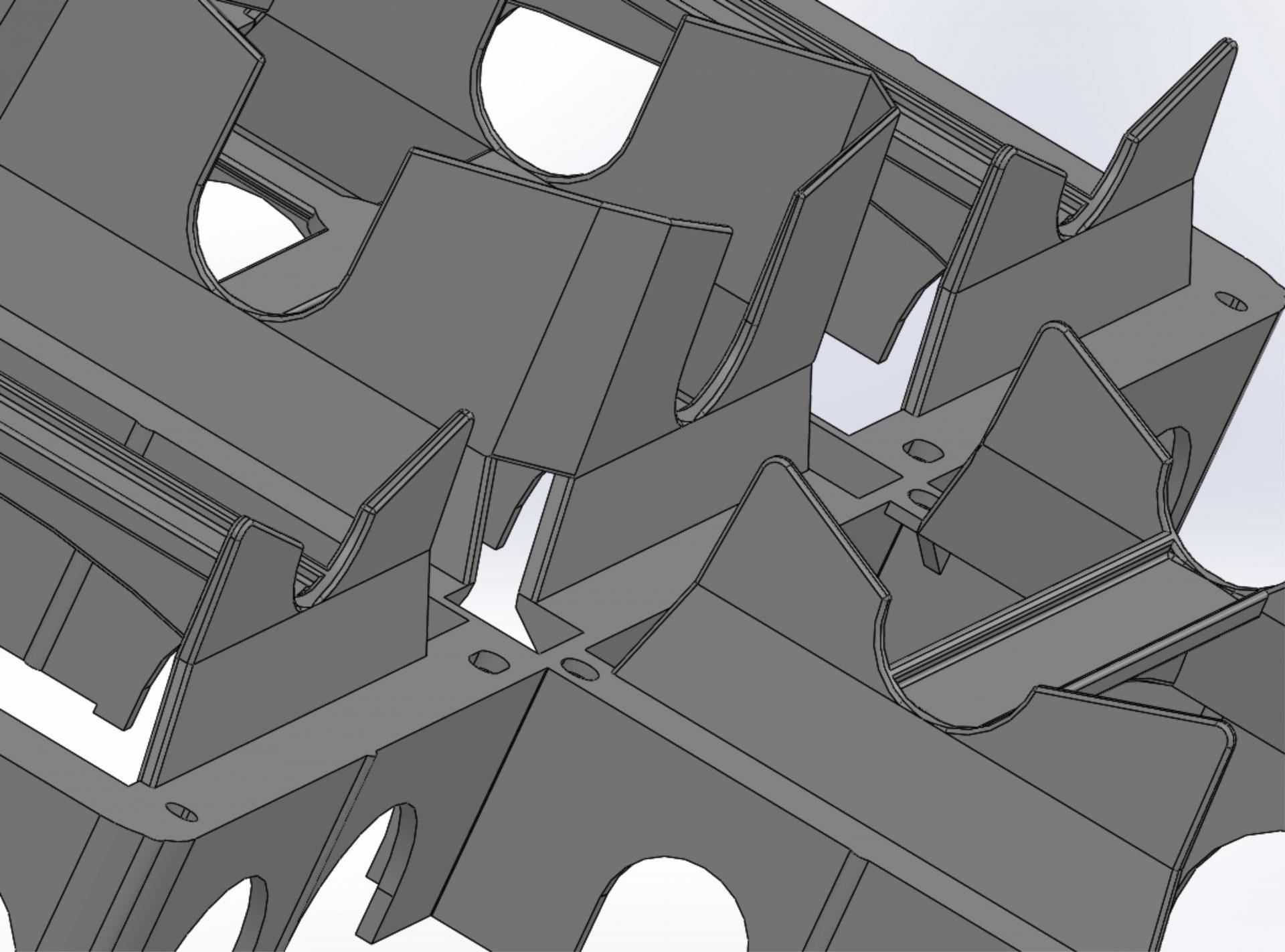

Okay, so you understand that thin wall sections will save you money and time, but you’re worried that your sales might decrease if your customers start to think that you’ve skimped on production. Well the good news is we can recreate your part with less material and still retain every bit of its intended strength, rigidity, and visual appeal. The secret lies in the use of expertly placed ribs, bosses, returns and coring. Coring is achieved by replacing thick wall sections with thin wall sections and supporting ribs, which keeps the strong looking form factor but at a fraction of the price.

For a quick example of what we mean, consider a making a cube from paper. You could make it by cutting hundreds of squares of paper and layering them one atop the other. Think about how much paper that uses. Or you could make it like an origami cube, and only use a single sheet. We do the same with injection moulded plastic parts, folding and returning the material so that each every single bit is directly imparting strength, and nothing is wasted.

Still not convinced? If you want to explore the option of reducing wall sections in your part, any of our designers will gladly talk through your project at your convenience and provide you with free advice, with no obligation whatsoever.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox