Crack open almost any plastic shape and you will the internal volume is mostly air, and anything that actually does any work inside the part is reinforced by a strange pattern of thin little walls.

Those little joining walls are called ribs, and they are one of the most important and powerful parts of any plastic design.

The story of ribs actually starts with the story of walls. For most plastic parts, the outside shape is pretty important. On the other hand, parts usually cannot be solid blobs of plastic for cost and manufacturing reasons.

The answer is to “shell” them, hollowing them out so only the parts that need to be there remain. But how do we keep the part hollow but make it strong?

This is achieved by ribbing the structure. The concept is simple enough. The designer looks at the part and maps out where it needs to be strong. They look at things like internal features which may need to support other structures, areas which will be gripped or compressed in use, weights which will be applied to them and stretching that the part may have to stand up to. They will also look at the direction those forces will be applied in.

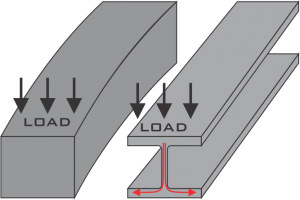

Then, the goal is simply to back up those areas with a rib that is in line with the load. Think of a beam solid, square steel beam used to hold up a roof. Engineers realised that as the force on the beam is coming down on it from on top, some parts of the beam compress, and others stretch, and a good chunk of it does nothing at all. Only metal that is in a position to resist the load is important. The rest of the material can be removed, leaving us with the familiar I beam shape and a lot less metal to buy for roofing.

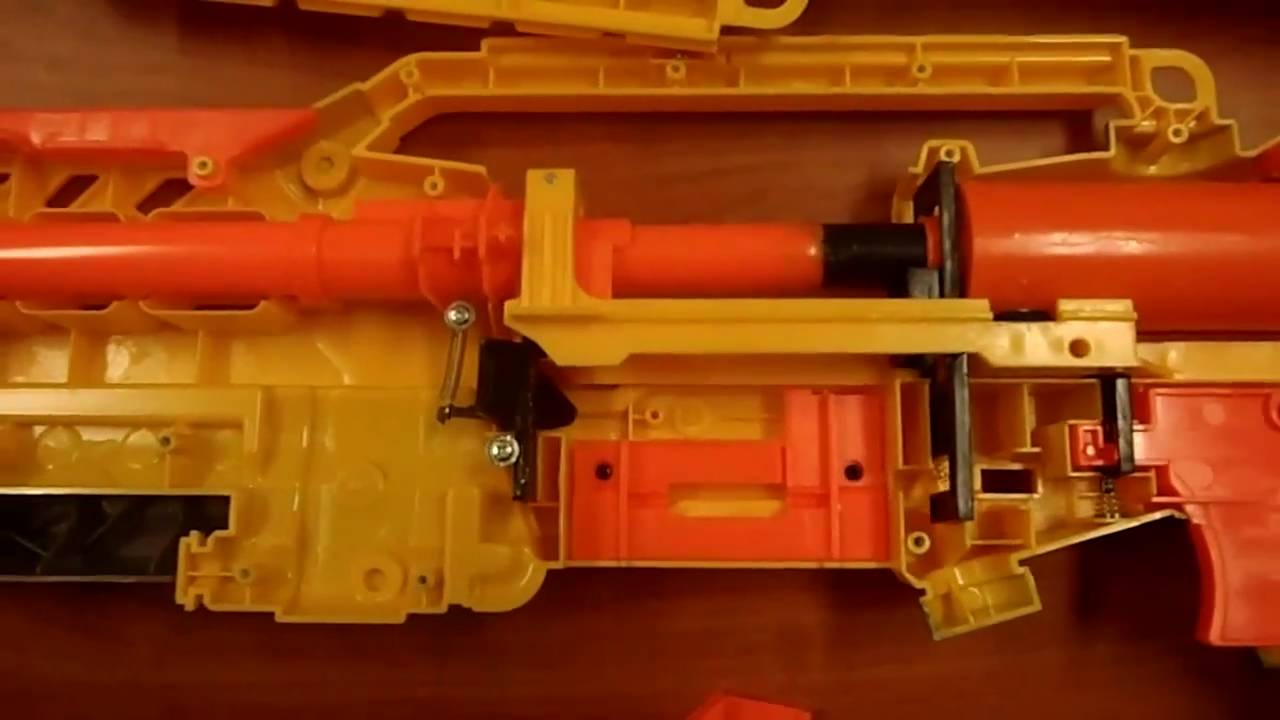

Ribs work the same way, carrying the load and drastically lowering the amount of plastic needed per part. If you look at the ribbing inside something as simple as a toy gun, you will see an unbelievable amount of detail in the ribbing. Ribbing is a hallmark of Injection moulded parts because this detail does not “cost” anything on a per part basis. One the tool is complete, each part will be made in seconds, and a perfect copy of the one before.

Like a lot of things, the concept is simple, but the devil lies in the detail. A great deal of time and experience goes into correct rib placement, ensure that end parts don’t suffer from sinks marks, warping or fatigue.

Plastic is an excellent material, and properly designed parts can be an amazing mix for strength and beauty. Getting the design right ensures that your product can be moulded on time, every time for less and maybe even with better physical characteristics than if it were just solid.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox