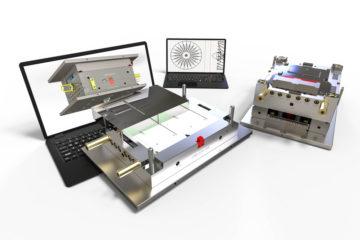

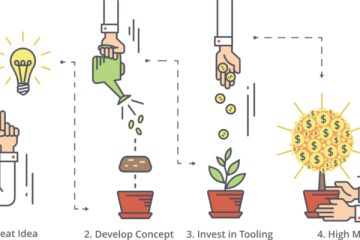

Part design can be a difficult process, particularly when you’re in charge of the business. And while it may be tempting to go for cheap substitutes and stick with formulaic designs, at the end of the day it’s your business that suffers. We’re going to take a look at the advantages of involving the tool maker when designing parts. By using custom made items and employing the tool maker’s creativity you can significantly broaden your horizons and increase the value of your business.

The potential to increase productivity through custom design

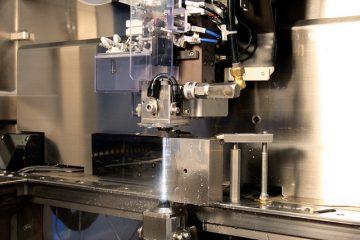

Parts and systems that are not custom designed are cheaper, but they won’t produce the best results for your business and the systems that go into it purely because that’s not what they were designed to do. Instead, by employing the use of a tool maker when designing parts you have quite an opportunity to significantly increase your productivity. Whether this is figuring out clever ways to make systems that allow your team to finish their work faster and smarter or ways to integrate processes that make the whole system significantly more streamlined, the productivity gains that can be made through a tool maker employing custom thought processes when designing parts are significant and should not be discounted.

While it may be more expensive in the short term to custom design parts that are specific to your purposes, over the long term you will end up saving money, time and effort that will eventually mean high levels of profit for your business. Ultimately, it comes down to what you want for your business and what level of success it will achieve. At the end of the day, what’s the point of doing something if you’re not going to do it right?

The potential to gain a competitive advantage over the competition

If you’ve figured out a stock standard part offers a cheap solution for one of the processes that are vital for your business, there’s every chance your competitor has as well and that they may have beaten you to the punch. If you really want to gain a competitive advantage over your competition you have to think outside the box and involve the tool maker when designing parts to make customised solutions for your business. The tool maker will be able to build technology, parts and machines that are ideally suited to your specific business operations.

When everybody’s using the same off-the-shelf parts it’s difficult for any one business to outperform another, but if you’ve got parts specifically designed for your processes you’ve immediately got a competitive advantage over your competitors. The more time, money and effort you invest in these custom designed parts, the more pronounced the advantages will become and ultimately the bigger the advantage over your consumers becomes. Don’t fight fire with fire if you don’t have to. Employ the tool makers when designing custom parts, and enjoy the significant advantage this grants you when it comes to producing a product or carrying out a service that considerably beats your competitors.

The ability to deliver goods and services quickly, with a faster reaction time

Another advantage that comes with involving a tool maker in designing custom parts are the significant productivity gains that lead to you ultimately delivering a faster, more efficient product or service with a significantly faster reaction time. Too often companies have stymied themselves by sticking to generic solutions for everyday problems, purely because it works out to be the cheapest alternative. When you involve a tool maker and get customised, effective parts that are unique to your business, you’ll be able to implement a variety of products, tools and systems that allow you to deliver results for the consumers much quicker than anything that can be achieved from your competitor’s offering. Having customised design elements in your process also makes it easier to think on your feet and react to changes in the market, potentially giving you the chance to make even more gains over your competitors.

Ultimately, the choice is yours. You can be part of the pack, or you can lead a business that is firing on all cylinders, with customised parts and processes that have been streamlined through the work of a tool maker. While it might take a bit of money to get set up, ultimately the gains will shine through and you’ll be able to enjoy a business that is second to no one else in the world.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox