3D printing has been around since the 1980s, and over time has transformed many industries and manufacturing operations. Today, it’s one of the world’s most substantial and transformative technologies. Discover where 3D printing technology is headed in 2020 in Australia.

But first, here’s a little information about the process…

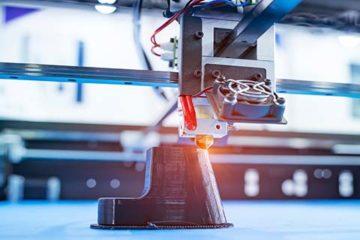

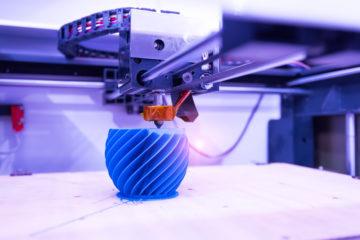

3D printing is a manufacturing technique used to create three-dimensional objects. Material is gradually added in layers to build pretty much anything you have on your mind. Including:

- Machine components

- Tools

- Toys

- Jewellery

- Medical models, equipment and parts

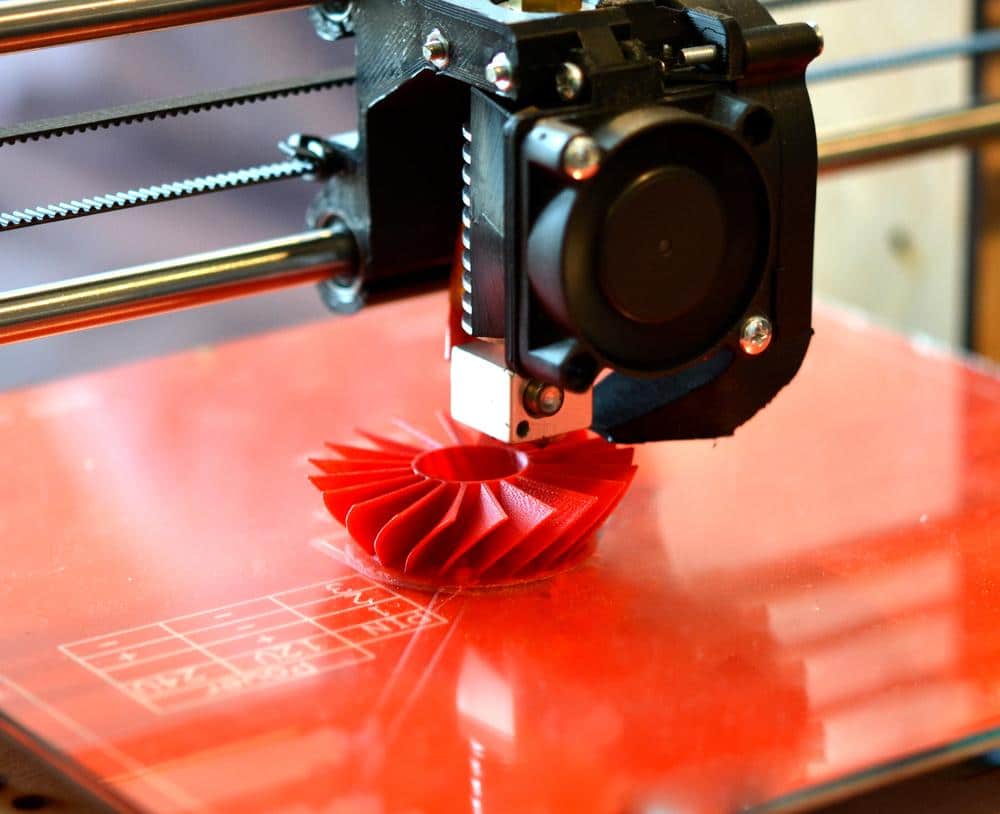

Stereolithography apparatus (SLA) 3D printing has been used commercially since 1986 and today the process has been fully adopted by small to medium-sized business and manufacturing factories. It uses range from product prototyping to mass production.

In 2020, improvement and evolution for 3D printing technology continues and manufacturers are working hard to expand performance in all sorts of ways…

New materials and improved 3D printer versatility:

Machines with the ability to print using a variety of materials, including metals, ceramics, chopped carbon fibre, and superalloys are already in use. Some even have the ability to combine different materials while building the same object…

XJet, uses a technique called NanoParticle Jetting, allowing both metal and ceramic materials to be used on the same machine. Building different parts of the same object out of materials of very distinct physical properties.

Driven by the fierce competition to develop machines that provide solutions for a greater range of industries, we’ll see an acceleration in scientific research into new materials and related technology for use in 3D printing.

Getting faster:

In order to fill the need to produce higher volumes in manufacturing, printers need to work faster. So, the race is on in 2020, and Australia is already up there in the front runners.

As reported by Business Insider Australia, an Australian company has developed a printer that can simultaneously print multiple layers, dramatically increasing the print speed while maintaining quality.

Expect to see this technology become even faster providing increased manufacturing possibilities.

Ability to operate in uncontrolled environments:

One of the disadvantages of the additive manufacturing process is the need for a controlled environment. To avoid unwanted contaminants and particles, many 3D printers require the build to occur inside a chamber. This limits what can be printed and where it can be used.

However, 3D printers that are not restricted by a controlled chamber are being developed. Some are already, successfully operating ‘on-site’ in mines and army locations. The ability to be self-sufficient by printing new components on-site in remote locations has enormous benefits.

Expect to see 3D printers operating in more remote, hard to reach locations and harsher environments in 2020.

Spurred on by fierce competition to develop machines that offer solutions to a wider range of industries, 2020 will see continued evolution in 3D Printing. New materials, improved machine versatility and speed, and the ability to operate in more uncontrolled environments will provide new opportunities to businesses large and small.

For more information about 3D Printing and how it can be utilised for your product idea

contact the team at Dienamics. Get in Touch

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox