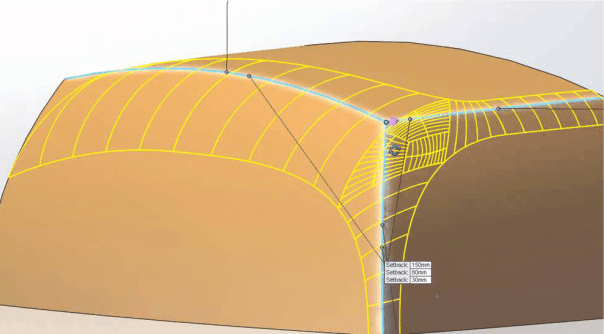

We touched on fillets on our previous article about radii in product design Fillets, like radii, are a technical term to describe surfaces that curve in certain predictable ways (namely, that it’s a perfect circle with a constant diameter or part of one). Fillets are really useful in Injection Moulding because where two walls or surfaces meet, there are often issues.

Firstly, the fillets make the intersection point stronger, as there is no sharp transition in the cross section or profile of the part. Sharp corners tend to focus stresses and tensions which may lead to broken parts or reject part. You might be thinking that your product doesn’t have any fillets in it because it’s meant to look very geometric and strong and durable, but you’d be surprised that when you look carefully, you’ll see tiny fillets in the corners of your product. Sometimes these will be intentionally tiny 0.25mm fillets, and other times there will be fractional 0.05mm radii, because the machinist just can’t machine the tool that makes your part down to that level of detail. And to be honest, it’s not the machinists fault either, most cutter bits and drill bits can’t cut down to that tolerance.

Fillets also make the moulding process a little easier. As you probably know, injection moulding heats raw plastic material to beyond it’s melting point and injects the molten plastic into the mould at high pressure. The aim of this is to make the part as quick as physically possible and have the machine cycle many thousands of times, hundreds of thousands of times even. By filleting the corners, you streamline the path the molten plastic must take to fill the mould. This reduces your cycle time, which reduces your unit cost. Stronger, cheaper, faster products is a Win-Win-Win right?

The down side of filleting is yes, they impact the look of your product. They can also add unnecessary weight to your product. If not done carefully fillets can cause sink marks on your product’s show faces. This is something to be especially cautious with when filleting ribs, under show faces, as the radius might not seem large, but it may affect the cross-sectional volume of a rib-wall intersection point significantly. If you want to learn more about fillets and how they help to shape your product and tool, come in for a quick (and free!) no obligation meeting with our head toolmaker and friendly design team or contact us online.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox