In our current manufacturing environment, plastics are being used to create everything from vehicle parts to buttons on clothing and even human body parts. For every application, a special and specific manufacturing process is required so that each part can be moulded based on its specifications.

If you’re interested in manufacturing a plastic part, one of the first things you’ll need decide on is what type of moulding will be best for your particular part.

With over 30 years experience in Industrial Design, Toolmaking and Manufacturing, Dienamics is your one source solution for all your plastic moulding needs.

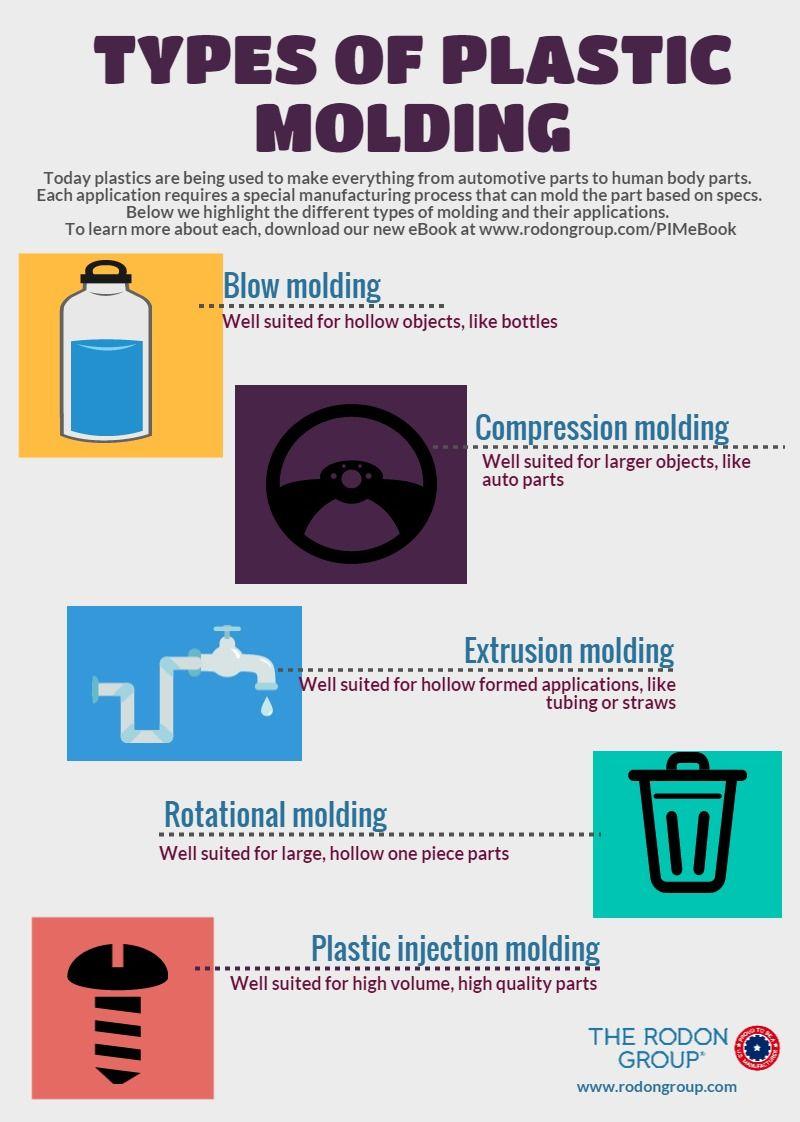

The following infographic provides a brief overview of the 5 different types of plastic moulding, their advantages and applications.

Want to know more about the 5 types of plastic moulding? Learn all there is to know about blow, compression, extrusion, rotational and plastic injection moulding through our blog.

Infographic source: The Rodon Group (https://www.rodongroup.com/blog/manufacturing-methods-of-plastic-molding)

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox