Rapid prototyping involves a number of processes that allow 3D models of designs and products to be produced. Typically, rapid prototyping will make use of a computerised program that creates these models from computer-aided design (CAD) drawings. Rapid prototyping is important because it is a useful option for turning designs into physical models.

The process

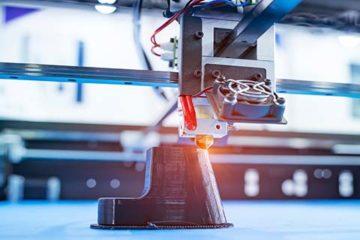

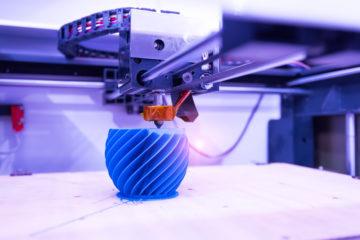

In a rapid-prototyping process, the machine uses the CAD design by reading its data. The machine uses the data to layer printing material to create the 3D item. The materials may take powdered or liquid form, and they might include plastics, metals, ceramics, wood, steel or titanium.

The CAD design will include information on each successive layer, giving the machine a complete picture of the cross-sections. After setting down each layer, the machine will typically fuse the sections together with a laser.

Benefits of rapid prototyping

Organisations and individuals use rapid prototyping to create models of products quickly. It compacts the design-cycle time and enables the creation of numerous and cheap prototypes. Some prototypes may be created within hours or days, when the same design can take weeks to create by hand.

Source:http://www.webserviceplus.net/what-is-rapid-prototyping/

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox