It once took a very long time from idea to production, with modern techniques, and even faster production methods, you could be turning out thousands of real items from your idea in a matter of weeks. You will most probably need some professional help, especially from those who understand modern rapid prototyping techniques to having real life experience with materials and real life usage. Rapid prototyping is fast becoming the norm to save costs in wasted time compared. Working with good ideas and testing them is at the heart of product design . Here is a basic look at the steps involved.

- Goal.

Your goal is to have at least one single tangible representation of the product that you will mass produce so that you can touch, feel, test and evaluate the way the final product will actually work without the costly process of actually making it. This will allow you to make modifications that were un-seen in your original idea. Your professional should know the most appropriate technique for your case, and has a variety of methods at his/her disposal such as - Communicating the idea.

Having an idea is no good in your head. Whether this is through the process of discussion, drawings and getting your idea down on, well, at least paper. Anything that you can use to clearly communicate your idea to your product designer is important. From drawings, notes, and even a field trip. - Modification based on experience.

It is recommended that you also listen to your industrial designer at this stage as they are more than likely to have experience in relation to some areas of what you are trying to do, and they may give intuitive hints on how to make your initial prototype more functional based on their culminitve experience. Don’t waste your own time and take some advice. Don’t be afraid to release some control. - Computerisation and single output.

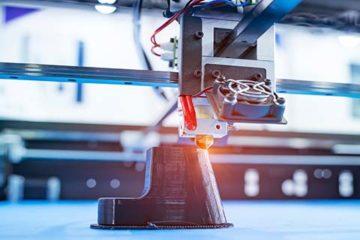

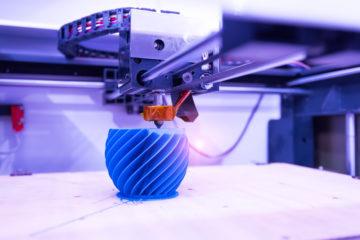

There are variety of 3D software programs that you could use to help describe your idea. The first real phase of getting to your prototype. Professionals will use CAD (Computer Aided Design) to work with the appropriate method of rapid prototyping the suits your idea best – often much faster and less costly than plastic injection moulding . This way that 3D image generated can now be directly produced into a tangible and readied for testing. - Testing and adjustments.

No matter how good your idea, you will probably always find that there is something that you could have thought of better, or something that you have can improve when you have a prototype. You can now modify and when you are confident with the final prototype you are ready to go into the expensive cost of production.

Having the right individual or company to walk you through these steps and understands what it takes in your case is extremely important. Your professional can save you much time and money and get it done right, and if they really know what they are talking about, they can probably do a lot more.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox