Injection moulding is an affordable, versatile, and efficient manufacturing process that has earned an admirable place within the business of any production company.

It’s used to make everything from Gameboys to gears, and with the process standing as one of the best options for businesses developing products. There’s a myriad of benefits to swapping over to it today.

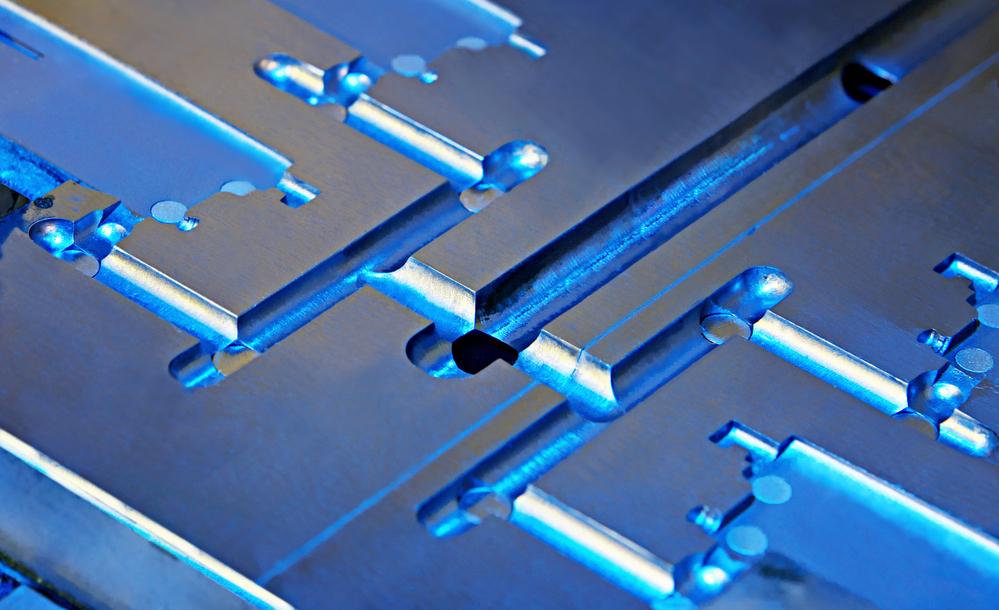

Notable products created by injection moulding

If you take a quick look around your house, you can probably find numerous objects that were made using plastic injection moulding – even the computer or smartphone you’re viewing this on. Countless products are completely reliant on this process for their manufacture; many which are common items we use on a daily basis.

- Car interiors: You may not realise it, but the interior of most cars are made up by injection moulded plastic components. In fact, every time you get into your vehicle you are surrounded by parts made from plastic injection moulding; the dashboard, radio buttons, window controls and plastic cupholders are all made this way. Injection moulding is also used to make some exterior car parts, such as the bumper, door handles, roof racks, lights lens and hub caps.

- Children’s toys: Most children’s toys – from Lego to Barbie dolls – are made from injection moulds. The reason for this is that plastic is the ideal material for children’s toys: it’s versatile, durable, waterproof and also easily cleaned.

- Medical devices: The healthcare industry relies heavily on products made from plastic injection moulding. In fact, many medical devices used both in facilities and at home are crafted from injection moulding. This process has allowed medical devices to be manufactured safely, precisely and efficiently. The medical industry relies on plastic injection moulded products as they are versatile, lightweight, sanitary & very cheap to produce.

Injection moulding is an ideal manufacturing solution as it can be used to produce a wide range of products efficiently and cost effectively. Here, we look at 6 ways injection moulding can benefit your business:

1. It’s affordable, easy to source, and widespread

The biggest advantage of injection moulding is a three-pronged feedback loop that keeps on benefitting you and your company the longer you use it.

Speaking of labour costs, another added advantage to the moulding process is how easily automatable it is. It requires very little supervision and oversight once the ball starts rolling. Our own machines are fully programmable with reproducible conditions that can be replicated with a touch of a button.

2. It’s very fast

We use injection moulding when it comes to creating products in bulk. The reason for this is the sheer speed of production and the cost efficiency of the process, parts can usually be produced in seconds.

The speed of production also means that the time saved on production speeds up your business processes. It means that you’ll be spending less cost on associated labour and profiting from the output.

3. It’s extremely efficient

Injection moulding produces very little waste. Not only is it one of the most efficient users of raw material, but any excess isn’t wasted; you can simply recycle it back into the machine for future components.

While the mould themselves can be expensive to produce, you’ll be able to recoup that quickly once you begin production, often in magnitudes of 10-20 times the savings in large batch scale operations.

Your labour costs will be barely noticeable when you consider that you won’t need to waste additional time joining or trimming your final products, as well as less rejects to deal with due to human error.

4. It looks good straight out of the mould

A lot of different casting products require finishing after the moulding process. One fantastic advantage of injection moulding is that they come finished right out of the mould looking great and ready to use.

5. It’s strong

As part of the moulding process, you can add fillers or additives to the moulded part via plastic injection process in order to create reinforced and stronger products, an option that most other processes lack.

6. Injection moulding is customisable

As a combination of the availability of customisation options and the ease of customisation in the process itself, there’s a lot you can do with injection moulding to mix up your project.

For starters, there’s a wide spectrum of materials and colours that you can use in the process, but assuming you fit the basic design criteria you’ll also have a lot of flexibility in how you approach your design.

On top of that, you can use different types of plastic throughout your cycle. Plastic can be co-injected so that a machine can process two different plastic types in the same process!

If you have an injection moulding project, contact Dienamics today for your high quality, low cost injection moulding solutions that can be customised to your businesses specific needs.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox