We have previously discussed some general ways to classify steel. In this article we are going to dive into the specific types of steel we use to make your products, why we use them, and what they mean to you.

The first thing to do is clear up some confusion. You may be thinking, “But I came to you to design a plastic product, what does metal have to do with me?”

The answer lies in mass production, and how we set up to make as many of your part as possible for as little as possible.

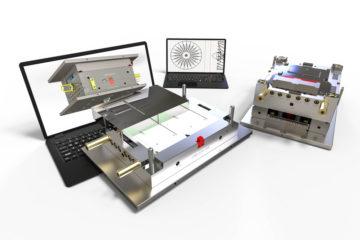

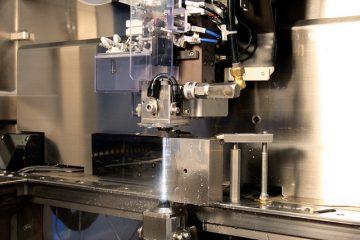

Basically, we make a tool. This is a high precision machine that will convert the base material (say, plastic) into your part. Without a tool you’re making parts by hand. Once you tool up, you are a captain of industry.

Each production process has its own stresses. Injection moulding uses hot plastic, so the steel used has to keep its shape when hot. Metal stamping uses force instead of heat, so the steel must be able to take repeated impacts without deforming. Some parts of a tool are supports for the working sections, so they simply need to be stable and not super specialised.

There are a few broad classifications of tool steels, based on the work they are good for. Each tool steel gets its special properties from a combination of its ingredients and the manner in which it is made. Varying amounts of other elements like Vanadium, Copper Chromium, Silicon, Sulfur and many others are added to the base steel. These affect the microstructure, making it better or worse at doing certain things. How these materials are added, and how the resultant steel is treated and cooled also affect that structure.

Below are then general classifications of tooling steels, and a quick explainer of some grades we use.

Water Hardening Group (W series)

This series is lower cost and not typically used in high precision tooling, due to its tendency to crack or warp under high stress.

Cold Work Group (O, A and D series)

These metals are used for cold forming. For instance, a metal pressing tool which cuts a shape from steel may have a die or blades made from CALMAX, a propriety steel in the D family specially designed for that task.

High Speed Group (HS or HSS Series)

These are the steels we use to shape other steels, and are primarily used for router bits, drills and saw blades.

Shock Resistant Group (S Series)

These steels are generally end use, so they are something we work on rather than makes mass production tools with. They are used for parts like a earthmoving auger blades and jackhammer bits, which will undergo repeated striking but not be subjected to high temperatures

Hot Working Group (H Series)

This series is designed to hold its shape and hardness while subjected to high pressure and heat, and is often used in plastic moulding. For instance, in an injection mould the parts of the tool that come into contact with the hot, molten plastic will be H13 or S136 Stainless, while the rest may be P20.

Special Purpose Group

This is the final, catchall series and is comprised of steels created to very specific industrial tasks. For example, we make extensive use of P20. It has been alloyed and formed specially for making the non working parts of injection moulds by being easy for machinists to cut to shape, while maintaining as much strength and polishability as possible. It’s a generalist, and is used to make the surrounds of machines.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox