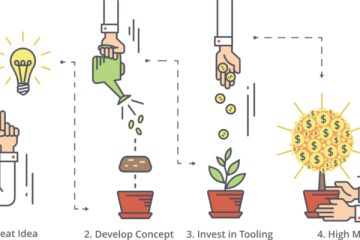

Investing in tooling is one of the most crucial steps for successful mass production. Throughout the working life of an injection moulding tool, it will wear from the repetitive high-pressure injection of hot molten plastic; and when I say repetitive, I mean it – the tools we do for our customers are made to last one million shots!

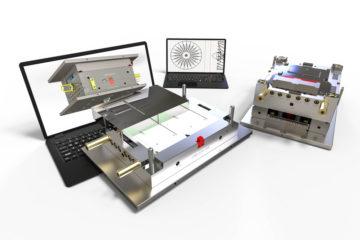

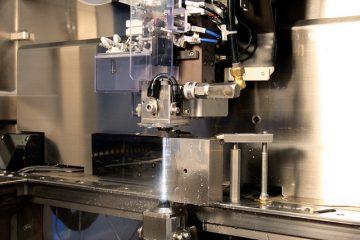

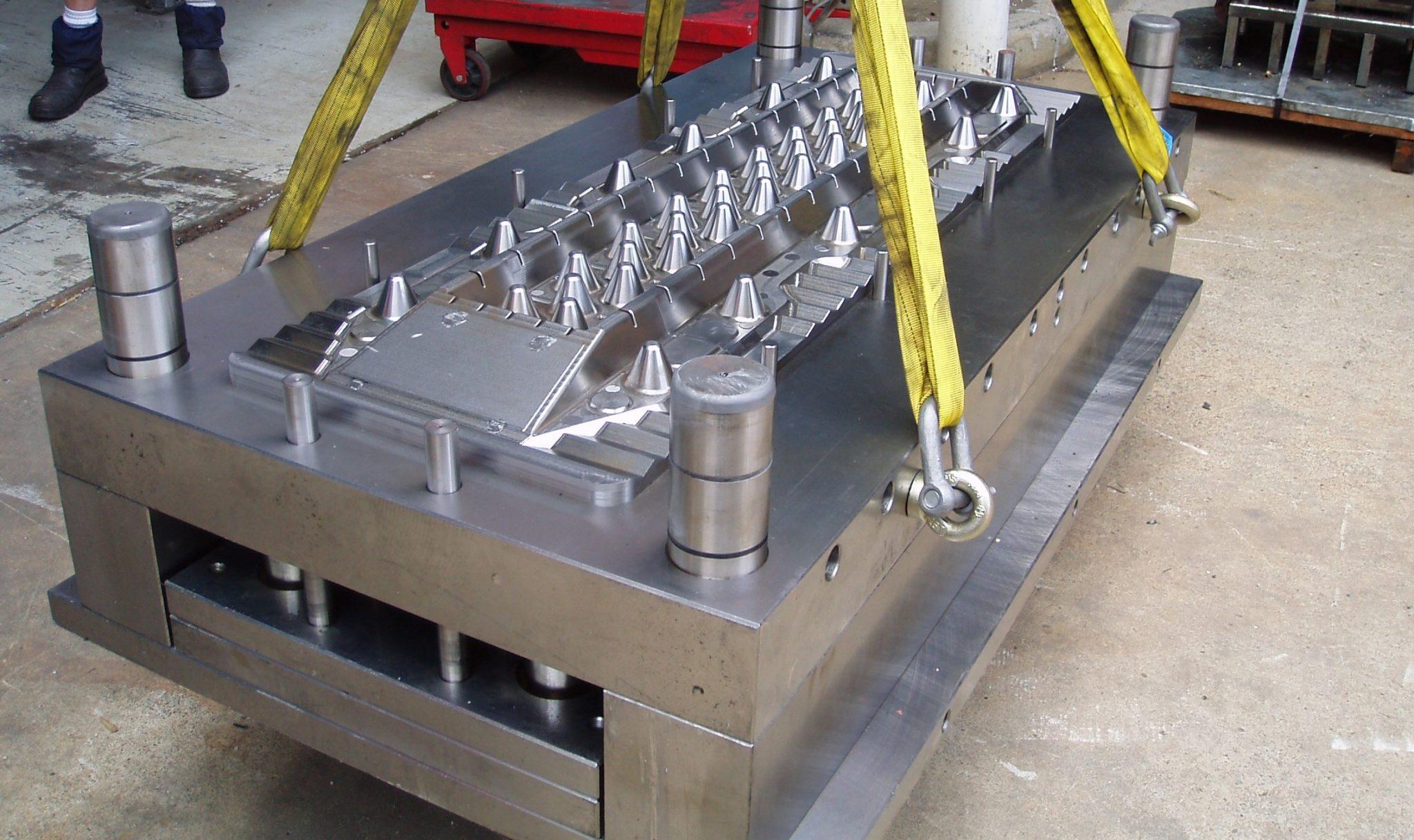

Injection moulds are very involved and precise tools. Having injection, ejection, cooling, and heating systems. Combined with their need to withstand the punishment they will be subjected to, tools take a substantial amount of time, labour, and material to build. Tool making, as a trade, requires extreme precision; good tool making means building tools to within 0.03mm dimensional accuracy to ensure parts do not flash. Tools generally cost in the thousands of dollars. However, the end result of this substantial investment is components that can be mass manufactured for dollars or even cents.

Spending more money on better quality, or more advanced tooling allows you to –

- safeguard the ability to manufacture good quality components for longer;

- ensure that your tool can be repaired easily to further its’ working lifetime;

- reduce the possibility of your tool being out of action for extended periods of time should it need repairs; and

- reduce the cost of moulded components due to faster cycle times, lower reject rates, and less post-processing/finishing required (e.g., trimming of flashing or sprues).

To read more about this, check out our blog on The False Economy of the Cheap Tool.

Non-Export Tooling

This brings us to the main focus of this blog – the difference between export vs. non-export tooling.

Non-export tooling is tooling that is built offshore (generally in China), that will never leave the country of origin. Non-export tools are exceptionally cheap, they are built quickly, cheaply, and often poorly, with non-standard specification local steels (i.e., Chinese steels). In many cases, they can also be made using a refurbished tool; refurbished tools utlise used, now obsolete, pre-existing mould bases.

Because of the poor quality, these tools will generally produce components with cosmetic defects like flashing – however because labour is cheap in China, moulding companies will employ people to do post-production/finishing work; polishing scuffs or cutting off flashing. As such, when compared to a better quality, fully automated, tool you will notice a slightly higher per part price due to this labour component. If you were to use the same non-export tool in Australia (with much higher labour costs) this difference would be drastically inflated.

Further, because of this manual labour component, the quality of the components you will receive is unpredictable and inconsistent; the quality of post-processing is going to vary depending on the individual doing the work. Conversely, if you instead invest in a better-quality tool, you remove this labour component and you remove this high chance of errors and bad parts.

Non-export tooling itself is considered proprietary. If you have been quoted for one, the quote will have a stated number of tool shots, after this number of shots has been run, the offshore mould maker through which you purchased the non-export tool will scrap the entire tool. To manufacture more components, you would have to purchase an entirely new tool. Non-export tools are not tools that you own as an asset, rather you pay for them as an expense.

Additionally, because the overseas mould maker you purchased the tool from retains ownership of the tool, you are unable to change injection moulding companies even if you’d like to. You may also be locked into purchasing a minimum number of components from them.

Export Tooling

It’s important to remember that simply using China to build tooling doesn’t meant that you’re inherently getting bad tooling. Really, you can generally say that Chinese tool makers are good tool makers, many of them are actually trained through American owned companies.

You can get very good quality tools if you can design the tool to the style and specification you specifically need, and you know which specific steel suppliers and grades to use for tooling steel.

Summary

When getting tooling quotes from China, whilst they’re generally cheaper (unless the tool is quite small), it’s important to ensure that price isn’t your driving decision maker – if the price is too good to be true, chances are it is. A lot of the time you will not even know you have been quoted a “non-export” tool unless you specifically ask the company quoting you if it is export or non-export.

Ultimately, it’s best to engage people who work in the industry, have worked with the Chinese before, have a strong knowledge of tooling and mass manufacturing, and can sign-off on tooling designs, steel used and heat treatment processes to manage your tooling to ensure you’re getting what you need, and getting quality.

You wouldn’t design engine, select the type of steel it’s built from, chose what hardness the steel needs to be, and install it into your car unless you were an expert in engine building – the same goes for injection mould tooling.

To learn more about tooling, and your options for building it in Australia, or having it project managed overseas contact us via our website ‘Contact Us’ form or call on (07) 3256 9222.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox