As you look around your garage, you probably see an assortment of tools and materials that could all be used in some way to make something, whether it’s a basic table for the backyard or something far more complex. Tools are the backbone of modern industry and trade, and while they are essential in almost any construction project, we don’t often stop to think about the process of making the tools themselves. What makes the makers? How has the product design process evolved over the centuries? Here, we take a brief look into the history of hand tools and how they are made today.

Defining Moments

In prehistoric times, many believe that one of the most important eras in our evolution was the utilisation of basic tools. It allowed our ancient ancestors to have much more of an effect on the world around them, helping them to survive in more comfort, and achieve more. As we evolved as a species, hand tools –and an ability to use them well–were essential components in the development of infrastructure, which spurred the establishment of trades like carpentry and blacksmithing which relied on an individual mastering the use of a certain tool or trade While hand tools were once forged out of the natural environment, these trades fine-tuned the creation of their tools using iron, wood and other metals which were heated and re moulded.

Modern Tools

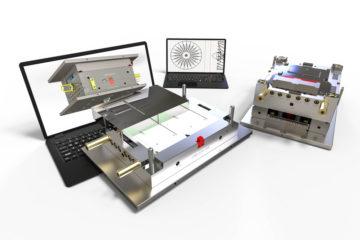

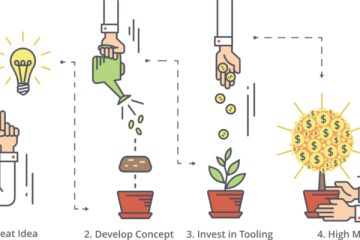

These days, the process is a lot more specific which means there is a uniformity in material, size and weight of hand tools which wasn’t possible before. Today, a hand tool will be designed on a computer, taking into account specific measurements and densities which will make it both efficient and easy to use.

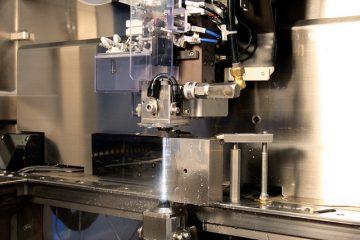

Once a design has been selected, the tools will usually be produced en masse through plastic injection moulding and metal injection moulding processes, wherein moulds can be created or customised and filled with liquefied metal or plastic.

Tool Design

These days, the process of designing a hand tool has an OH&S component, and is based in careful accident analysis in order to ensure tools are designed with the highest levels of safe usability. Most hand tools are designed in order to be easily operated using only one hand, and the general feeling among designers and retailers is that the simpler a tool is to operate, the better it will sell.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox