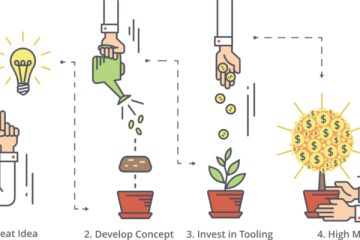

For a lot of companies, products are their main source of revenue. Therefore, it makes sense that the process behind their product design should be done with great effectiveness and efficiency. Before hitting the shelves, a product must go through various types of process and one of them is plastic injection moulding.

From big jars to small baby pacifiers, the injection moulding process is an indispensable part of product production. Without it, our products will not get the desired shape we see in the finished product.

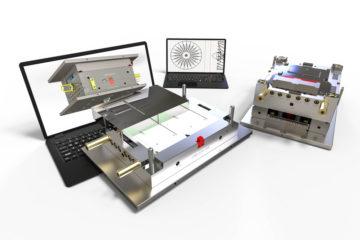

The use of laser machining to make plastic injection moulds has been around for a number of years, but their use, until recently, has been fairly limited. This is due to the uncertainty surrounding new technologies in general. So if you have never heard of laser machining, here are six frequently asked questions about the process:

1. What Applications are Best Suited for Laser Machining?

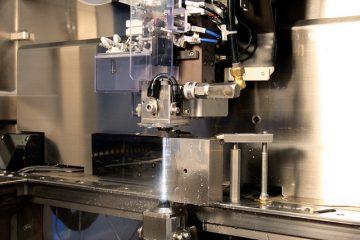

Laser machining can be used for cutting, decorating, bar coding, engraving and welding. The process itself is very versatile and there are only a few products that cannot take advantage of laser machining.

2. How Does Laser Machining Help with Product Moulding?

Cutting and shaping are essential parts in any product design system. A higher level of accuracy is mandatory when it comes to moulding, and laser machining is one of the most accurate cutting and shaping processes available today.

3. What are the Advantages of Laser Machining Over Other Processes?

Laser machining has several advantages over conventional metal cutting and fabrication processes. The laser machining’s cutting process is extremely flexible and, unlike other processes, it is widely used in non-metallic materials.

4. Is Working With Laser Machining Safe?

There is a general misconception in the public that working with machinery is not safe. This is totally untrue. Although there are cases in other industry of workers being injured and even dying in workplace related accidents, these accidents are becoming rarer and rarer.

But with laser machining, the threat to worker safety is virtual non-existent. The machine is safely tucked away and out of reach. There is absolute no danger in working with laser machining.

5. Can Laser Machining Beat the Competition?

The short answer is yes, it is the most viable option with so many extraordinary features. Laser machining is more than capable of giving your competitors who use another process a run for their money. The whole laser machining process for product design is automatic and computerised. This process can easily fit the requirements for small scale manufacturers.

6. What is the Typical Processing Time of the Laser Machining Process?

Usually the processing time depends on job complexity. Laser machining is capable of producing complex parts in a matter of minutes. Certain jobs, like logo engraving, are perfect for laser machining and can be completed much faster than with other processes.

Laser machining is still a relatively unknown process for the general public. Hopefully this article has shed some light on the innovative and fascinating world of laser machining.

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox