So, you’re sitting in front of your favourite CAD program, sipping a bottomless cup of instant coffee after a marathon design session, which has taken days, maybe even weeks and finally, you’ve finished a groundbreaking product that is going to change the world and you can start to plan that first superyacht purchase.

You spend 5 minutes checking out the view from cloud nine before looking back down to earth at your trusty home-office micro-factory, your Amazon-bought 3D Printer and think:

“Let’s prototype, print this sucker out, get an injection moulding tool made, and go take over the world!”

If only the path to manufacturing a successful product were as straightforward as this. You need a fully functioning, real-world representative prototype before you can move on from designing to injection moulding your product. You need to test and amend any finer details of the design so you can ensure your world-changing product is going to look, feel and function how you intended.

The question is, is your FDM 3D Printer really up to this task? Or should you be looking into other prototyping methods that will get you a real-world representation and subsequent moulding tool, so you can start choosing the colour of your yachts’ deck chairs as soon as possible?

In today’s blog, we are going to look at what prototyping methods you should be considering if want to bring your product design aspirations to life.

What is FDM 3D Printing?

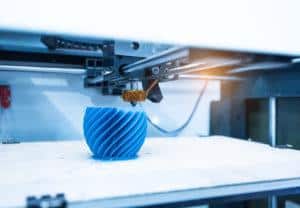

FDM (Fuse Deposition Moulding) 3D Printing, is a form of 3D Printing where the plastic filament is fed into a heated nozzle, melting the plastic so it can then be extruded along a tool path (moving in the X and Y axis direction) to create a custom shaped layer. When the layer is completed, a new layer will start on top of the previous layer (moving in the Z-axis direction) and this depositing of plastic, layer upon layer, will continue until a 3D Object or Model is created.

The process is great for making models and rough prototypes but lacks the finesse when it comes to making final professional-level prototype representations. The issues involved with this process include:

- Inconsistent layer heights, caused by inconsistent filament extrusion rate, leaving the product not being the correct size or shape.

- Poor mechanical properties. The layer-by-layer process means, when twisting force or pressure, it is likely to break along the layer lines because the layer bonding can be weak.

- The surface of the prototype will not be smooth and have “layer lines” which will require further processing to achieve a representative model. This processing may affect the models’ size and shape when precision is required.

Alternative Prototyping Processes

There are 3 types of prototyping methods you should consider when creating a production-worthy prototype –

SLS (Selective Laser Sintering)

- SLS works by sintering fine layers of material together (usually Nylon but can be metal) to build a 3D model.

- Layer heights are microscopic, 0.08mm vs 0.4mm for FDM. The laser sintering process enables this and means higher resolution models and precision parts are achievable. The fine layers can still be seen on the final product but are much less noticeable and easier to post-process.

- Mechanically, SLS parts are very strong and can be twisted and bent without breaking. Nylon has excellent mechanical properties for prototyping.

CNC Machining (Computer Numerical Control)

- Parts are cut out of a material (can be plastic, metal, or wood) using a spinning cutter, following a computer-generated path.

- Precision product representation can be achieved, thanks to its accuracy.

- Strong mechanical properties, but not as good as vacuum casting

Vacuum Casting – resin is drawn, via vacuum into a mould to create a part

- A sacrificial model is used to make a silicon mould, which can then be used to make multiple model casts.

- Mechanically represents final injection moulded well, because the resin being poured into the mould will flow in a similar way to injection moulding – the polymer chains will be in the same direction of the plastic flow, giving and truer product feel.

- Excellent smooth or textured surface finish can be achieved.

- Highly accurate to achieve precision parts.

When planning the next move in your product development process, you should really be asking yourself the following questions:

- “Does this FDM 3D Printed model really pass the standard needed to go on to Injection Moulding Tooling?

- ”Does this product model truly represent my product and all its requirements for looks, feel and function?”

These are critical questions that need to be answered before spending thousands of dollars on tooling costs. If you are confident in your groundbreaking design, it’s time to take the next step. Consider engaging with a professional to develop a real-world prototype. You’ll be lounging on your superyacht deck in no time!

If you want to learn more about how important professional prototyping is as a part of the design process, download “Prototyping – The Knowledge Series” from our website.

At Dienamics, we offer a range of comprehensive services in every step of the product manufacturing process. These include:

- Product design, including concept assessment and project scoping

- Prototyping, process and materials testing

- Manufacturing, injection moulding, production, assembly, and packaging

Contact us today if you have a product you’re looking to get designed & manufacture!

Subscribe to Our Newsletter

Get the latest news from Dienamics into your inbox