Call Us 07 3256 9222

-

Get a Quote

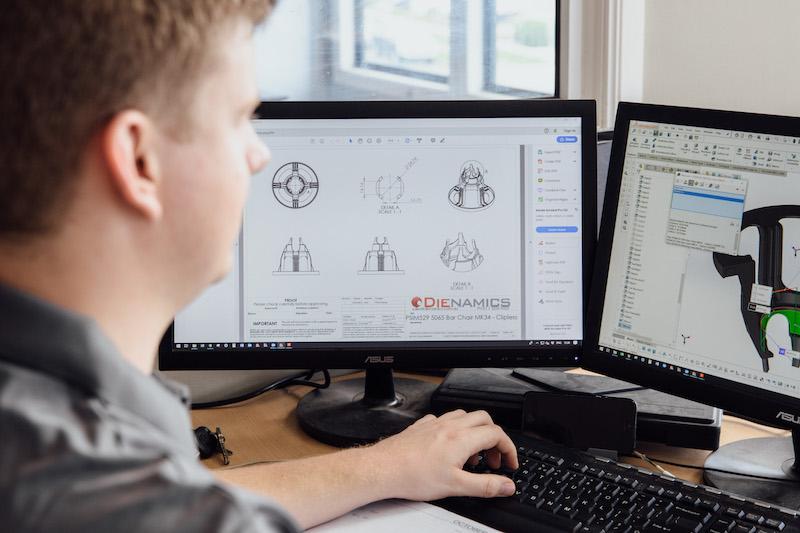

Providing that you have a CAD model, we can turn around 3D prototypes in one to two days to a week. We can even do more complex, highly aesthetic prototypes in 2 weeks. We can provide prototypes in the following methods:

CNC Computer Numeric Controlled machining

Vac Cast Silicone Mould Vacuum Casting,

FDM Fused Deposition Modeling

SLS Selective Laser Sintering

SLA Stereolithography

DMLS Direct Metal Laser Sintering

Click HERE to download our free Prototype Knowledge Series

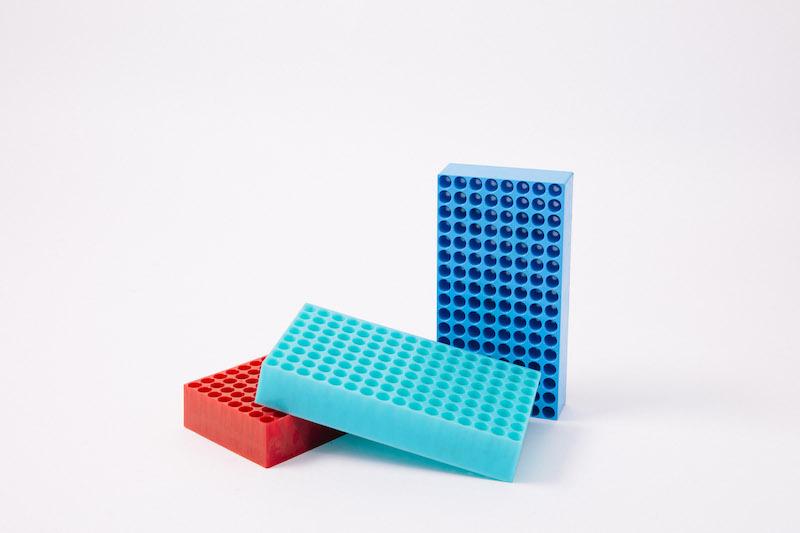

Proof of Concept Prototypes are basic prototypes done to test an idea or theory of how something might work.

Next you must test your product in the real world. You may have to assemble your product with fasteners and PCBs. Your product may have to interact with robots and be picked up and moved by a computer. Your product might have to stack neatly in a box or with 11 other boxes on a pallet to be transported. These are all key considerations and criteria that your product must meet.

We’ve had clients where key goals were linked to the product surviving extreme temperatures or exposure to harsh chemicals. There is no better way to show that your product will work than making one out of that material and physically testing it out.

This could be anything from making a vac cast mould and moulding a short run of parts in a polyurethane-based material, to setting up simple jigs and fixtures to do short production runs of parts. We can also produce enough prototypes so you are able to perform thorough tests. Some of our customers will even produce a single cavity injection mould and do a run of a few thousand to see how their clients like them.

The most important part is getting highly accurate geometry with a nice surface. The best way to do this is with CNC machined or Vac Cast prototypes as they make parts with incredible detail. Once you have a fine product we can paint it and cover it in clear coats or other finishes to make it look incredible – ready for the boardroom meeting or the photoshoot for the product catalogue.

Book your free brainstorming session today.

Get Started