We’re an industrial design firm with over 40 years of experience across industrial design, toolmaking and manufacturing. Based in Brisbane, we serve businesses in our local area and across Australia, including in Sydney.

We specialise in bringing our clients’ visions to life through a combination of time-tested processes and deep technical expertise. We are well practiced in collaborating with businesses remotely to impress them with outstanding product design, regardless of where they are located.

Our journey of transforming innovative ideas into tangible products has benefited countless clients across Sydney and the rest of Australia, creating lasting partnerships across generations of their product portfolios, built on trust and proven results.

How it works

The process for designing, developing, and launching a product is not a straight line. It’s a maze with twists, turns, forks, and dead ends. You need to navigate concept development, aesthetic exploration, optimising user experiences, cost scoping, design and engineering for manufacture, CAD development, prototyping, supplier management, compliance, patents and IP protection. Each product development journey is unique, so there is no set guide to follow.

At Dienamics, we understand the value of having each stage of product development done under one roof, with experts that have navigated the process countless times before. This approach accelerates timelines, simplifies communication, and ensures a unified vision between us and our customers.

We offer an in-house, end-to-end product design and development service, whether you’re based in Brisbane, Sydney, or further afield. That process looks like this:

Initial Consultation

It all begins with an initial meeting where we discuss your product idea and goals. We’ll identify the best path forward, and discuss how our services can be customised to meet your needs

2. Concept Assessment & Design Brief

Together we’ll define your project's scope, objectives, and requirements in a formal Design Brief. This becomes the roadmap for the journey we will take together.

Project Scoping

Depending on the project, we then conduct a scope of the potential manufacturing and production costs. This helps you make informed decisions about your product’s viability and understand what’s to come.

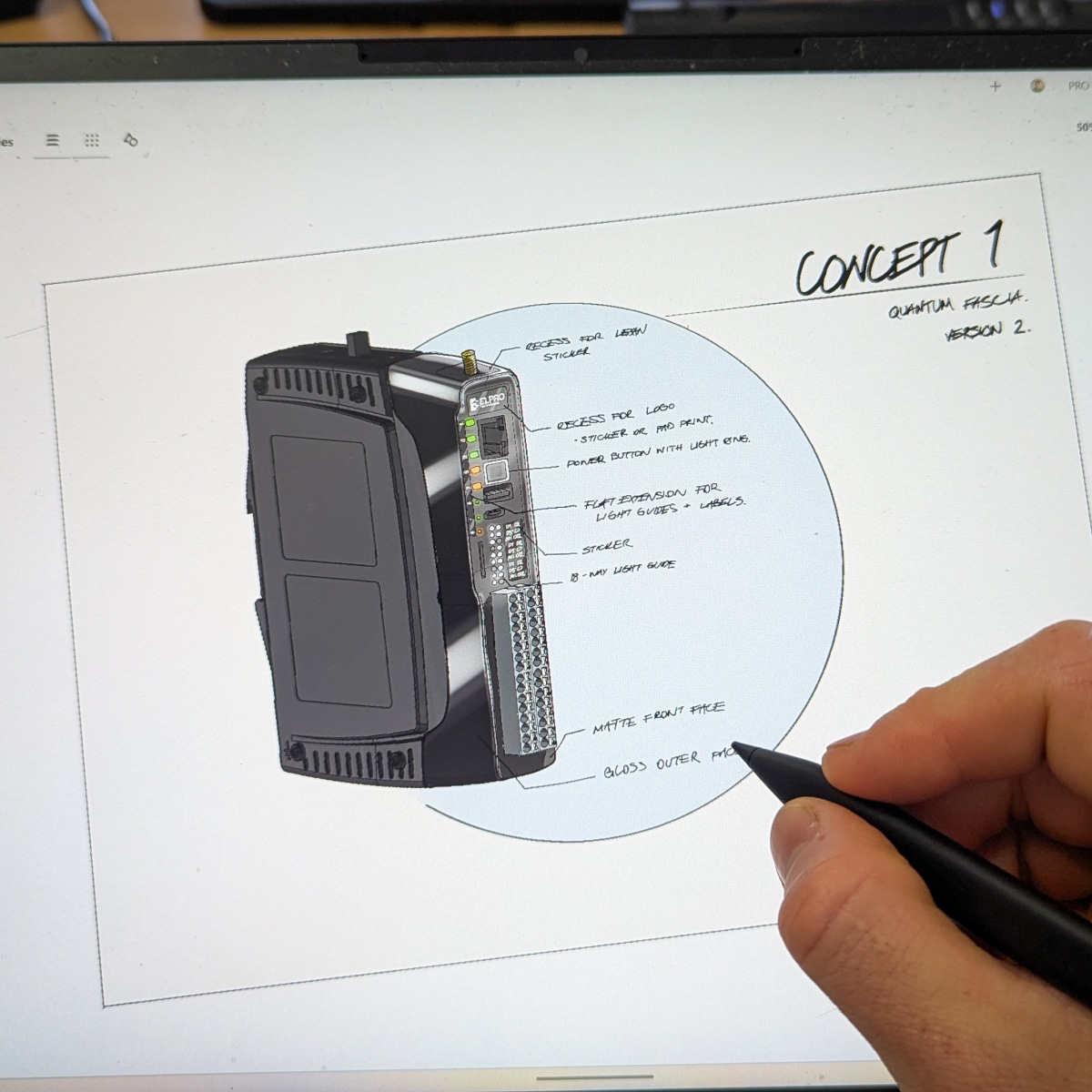

Concept Design

Concept development begins by exploring the idea to find the best solutions. This includes solving mechanical design problems, exploring manufacturability, and exploring aesthetic styles for the product design and branding.

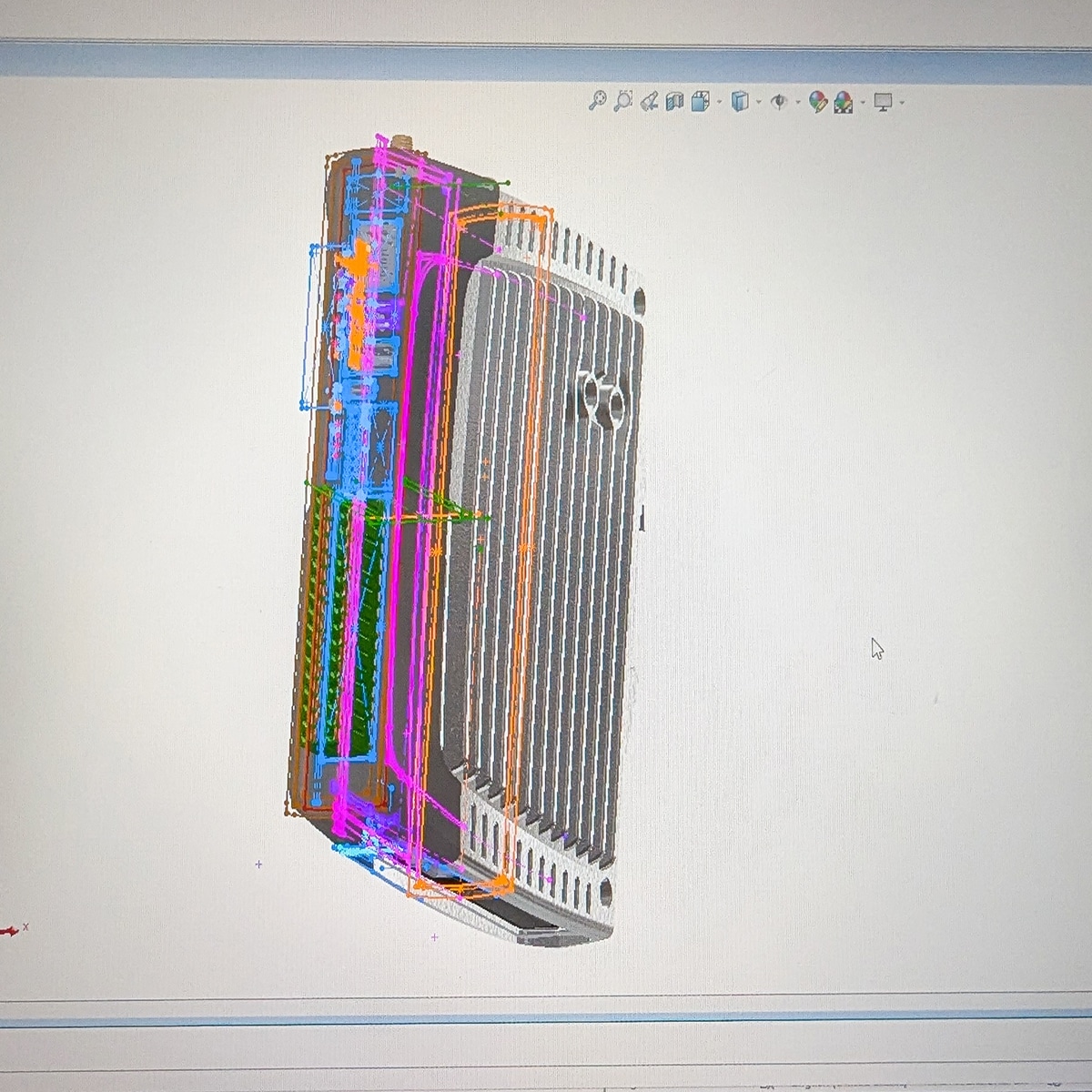

DFM 3D CAD Design

Once you approve a concept design, we create designved-for-manufacture (DFM) 3D CAD drawings. Our deep knowledge of manufacturing and toolmaking means our CAD is precise and production ready.

Initial Prototyping

Initial prototypes are made from 3D CAD, using various methods such as 3D printing, CNC machining, vacuum casting, laser cutting, and fabrication in plastics, metals, rubbers, foam and more.

Design Refinement

The prototypes are reviewed and tested, and any necessary design refinements are made. Design is an iterative process, and the purpose of prototyping is to identify areas for improvement.

Iterative Prototyping

After any modifications, the design is re-prototyped. This cycle of design refinement and prototyping continues until the design is approved and ready for manufacturing.

Manufacturing & Production

Our team builds the moulds and tools needed to manufacture your product design, or we manage this process through our trusted supplier network. Then, we produce your products and can even assemble and package them for you.

Being experts in design and manufacturing, we’re well-placed to jump in at any stage of the design process. Whether your product idea at this stage is simply an idea in your head, you want an expert review of your design, you’re looking for another firm to redesign your design for manufacturing, or if you’re looking for a prototype supplier to produce your design – we’ve got your back.

We’re happy to work with you as your design lead, or hand in hand with your current designers or engineers. We regularly collaborate with Sydney-based clients remotely, ensuring smooth communication throughout the design process.

Concept Design

You“I have an idea, and I need experts to develop my product.”

DienamicsWe’ll work with you to understand your product and your customer to develop robust product concepts that are more than just a pretty picture, but, perfect for your customer, and designed for manufacture.

Design Analysis

You“My product is already designed, but I’m not confident it is designed well for manufacturing.”

DienamicsWe will conduct an in-depth review into your design and give expert recommendations to your design team on how to optimise your design for reducing your tooling and manufacturing costs and improving performance and quality.

DFM Design

You“I have a concept design, but no 3D CAD Data that is designed for manufacture.”

DienamicsNo worries – we’ll take your concept and build precise 3D CAD data that is expertly designed for your chosen manufacturing method.

Prototyping / Manufacturing

You“I have 3D CAD Data and am ready to get prototypes made, or progress to manufacture.”

DienamicsIf your design work is already complete, we can arrange the prototyping and manufacturing of your products, working in with your design team to get your products out in the world.

Why Choose Dienamics?

Dienamics offers a complete, in-house solution – from concept development to industrial design, CAD modelling, prototyping, and injection moulding. If you’re searching for a Sydney design firm, our Brisbane-based team delivers not just expert design but a true end-to-end service. While many firms outsource parts of the process, we keep everything in-house for faster turnaround, clear communication, cost efficiency, and tighter quality control.

With 40+ years’ experience, we regularly work with Sydney startups and established brands – while we’re not a Sydney-based design firm, distance has never held us back. We specialise in Design for Manufacturing (DFM), providing practical, production-ready designs backed by in-house toolmaking, rapid prototyping, and plastic injection moulding.

Need a product design company that delivers? Contact Dienamics today. Get Started.

Track Record

30+ Years Proven Track Record

Family Business

A Trusted Family Business

Expertise

Designers with Manufacturing Expertise

End-to-End Service

In-House Manufacturing & End-to-End Service

Market

Faster Product to Market

If you want to work with experts to get your product off the ground and performing, then get in touch with us for industrial design, product design, tool making and manufacturing. Whether you’re an inventor, a local business, or an international enterprise, we offer specialised design services to help you take your concept from an idea to a reality.

Talk to our expert team today.